After-Tax IRR of 111% and sub-$30 million CAPEX

Toronto, Ontario— (Marketwired – October 3, 2022)

Minera Alamos Inc. (“Minera” or the “Company”) (TSXV: MAI) is pleased to announce the positive results of an independent Preliminary Economic Assessment (“PEA”) for its Cerro de Oro Project (the “Project”) in Zacatecas, Mexico. The PEA was prepared in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) by Scott Zelligan, P.Geo., Lawrence Segerstrom, M.Sc.,CPG, Peimeng Ling, P.Eng., Alex Duggan, P.Eng. and Toren Olsen, PG. A Technical Report with the details of the PEA will be filed on SEDAR under the Company’s profile within 45 days of the date of this news release. (Note to reader: Unless stated all currency references are in US dollars).

Highlights of PEA

- Production highlights

- Average annual gold production approaching 60,000oz (~60,000oz to 70,000oz in Years 1 through 4).

- 8.2 year mine life based on initial mineable total of 59 Mt of mineralization (0.37 g/t Au) heap leached at an average rate of approximately 20,000 tpd – +0.40 g/t Au in Years 1 through 4.

- 477koz of gold produced in loaded carbon/doré.

- LOM strip ratio of 0.3:1 (waste:mineralization)

- Robust economics using metals prices of $1,600/oz Au

- LOM All-In Sustaining Cost (AISC) of $873/oz – averaging $763/oz in Years 1 through 4.

- After-Tax NPV at 5% of $150.5M and IRR of 111%.

- Low capital intensity project with rapid payback:

- Pre-production capital costs of $28.1M (includes 30% contingency).

- Payback period of 11 months.

- Used crushing plant already purchased reduces up-front capital requirements.

- Significant Upside

- Mineralization appears open in multiple directions as well as to depth.

- Additional metallurgical testing to examine amenability of gold recovery from deeper sulphide zones of mineralization not accounted for in current resource calculations and mine plans (some early indications that material may prove to be leachable).

- Updated Inferred Mineral Resource estimate containing 67 million tonnes of 0.37 g/t Au (790 koz of contained gold) based on an upward revision of the base case resource metal price to $1,700/oz.

“Leaning on our team’s collective experience in mine building in Mexico with capital and operating costs informed by the recent construction and ramp up of the Santana gold mine, the Cerro de Oro PEA is a game changer for Minera as we strive to reach our initial target of a +100,000 oz/y gold producer,” commented Doug Ramshaw, President. “Given the rampant inflationary pressures across the industry, it is a testament to Minera’s smart and nimble business model that a new mine could be developed at Cerro de Oro for the low capital intensity presented in the PEA.”

Table 1 – PEA Economic Parameters Summary

| Cerro de Oro PEA Study | Life-of-Mine |

|---|---|

| Gold Price1 | $1,600/oz |

| Mine Life | 8.2 years |

| Total Mineralization Processed | 59.3M |

| Total Waste Mined | 17.9M |

| Strip Ratio (Waste/Mineral) | 0.30 |

| Average Annual Tonnes Processed2 | 7,300,000 |

| Average Daily Tonnes Processed2 | 20 ktpd |

| Heap Leach Gold Grade3 | 0.37 g/t |

| Gold Recovery | 68% |

| Average Annual gold production (oz)2 | 58,400 |

| Total Gold Recovered | 476,610 |

| Pre-production Capital | $28,080,000 |

| Sustaining Capital | $14,700,000 |

| Average AISC4 | $873/oz |

| After-Tax NPV (5%) | $150,500,000 |

| After-Tax IRR | 111% |

| After-Tax Payback Period | 11 months |

| Exchange Rate (MXP/USD) | 20 |

| After-Tax NPV (10%) | $115,500,000 |

| Net Cash Flows (undiscounted) | $200,000,000 |

Notes:

- Base case price for gold was assessed using long term consensus pricing factoring in a modest discount against the average of available bank and brokerage firm estimates.

- Life-of-Mine Averages exclude partial production in year 9

- LOM average combined grade of run-of-mine (“ROM”) and crushed material sent to leach pads

- “AISC per ounce” is a non-GAAP financial performance measures with no standardized definition under IFRS; additional reference info at bottom of release

PEA Cautionary Note:

Readers are cautioned that the PEA is preliminary in nature and includes inferred resources that are considered too speculative to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the PEA results will be realized. Mineral resources are not mineral reserves and do not have demonstrated economic viability. Additional work is needed to upgrade these mineral resources to mineral reserves.

Capital Cost Estimates

Total pre-production capital costs at the Cerro de Oro Project are estimated at $28.1 million. Sustaining capital costs over the LOM are estimated at $14.7 million for a total Project capital cost of $42.8 million. The pre-production capital cost estimate includes the construction of a stand-alone gold recovery (to carbon) facility, Phase 1 of the heap leach pad construction and all necessary site infrastructure to bring the mine into production.

Preliminary site layouts for the project were completed and included suitable areas for life of mine leach pad areas, required pond volumes and other infrastructure items in addition to the process plant and crushing operations. Cost estimates are primarily based on cost factors/data obtained from the company’s recent project construction experience in Mexico including the Santana gold project completed in 2021. To reduce initial capital requirements all open pit mining operations and associated capital costs are the responsibility of an independent mining contractor. In addition, the company plans to utilize (with some modifications) an existing crushing plant purchased previously and personnel will stay in the local municipality eliminating the requirement for any significant mine site camp facilities.

Table 2 – Initial and Sustaining Capital Costs (CAPEX)

| Area | Initial ($US) | Sustaining ($US) | Total ($US) |

|---|---|---|---|

| Preproduction technical work and engineering (geo tech drilling, etc.) | 1,500,000 | 1,500,000 | |

| Infrastructure and Misc. Construction (excl. crushing) | 3,000,000 | ||

| Process Plant | 3,400,000 | ||

| Pad construction | 7,000,000 | 13,200,000 | 21,200,000 |

| Pond construction | 2,700,000 | ||

| Crushing and Stacking Refurbishment | 2,000,000 | ||

| Substation, Misc. Power | 2,000,000 | ||

| Contingency (30%) | 6,480,000 | ||

| Total Project | 28,080,000 | 14,700,000 | 42,780,000 |

Operating Cost Estimates

The total unit operating cost for the Project is estimated at US$ 6.66/t of mineralised material (including general and administrative costs – “G&A”). Operating costs were developed based on first principles where possible including estimated staffing levels, reagent consumptions and power requirements. Unit costs and allowances for G&A, maintenance supplies, etc. are based on data from current Minera Alamos facilities (Santana gold project) and other similar heap leach operations in Mexico. Power requirements for the process operation (excluding crushing) were estimated based on operating equipment motor sizes and plant availability, and costs assume diesel generation with a delivered diesel fuel cost of US$1.10/litre (approx. US$ 0.30/kWh). Power for the crushing system is assumed to be taken from the nearby power grid at a price of US$ 0.13/kWh. An overall contingency of 20% was applied to the operating cost totals to account for additional cost items such as outside contractors, laboratory consumables, vehicle fuel requirements, etc.

All mine operating activities are assumed to be the responsibility of a third party mining contractor. Contractor rates include drilling, blasting and transportation of the waste/ore. Costs for the Company mine services group were prepared separately and included. LOM operating costs are summarized in Table 3 below. Actual annual costs in the economic models for the project will vary based on the proposed annual mine schedule and utilize the unit costs detailed below.

Table 3 – Operating Costs (OPEX)

| Area | US$/t mineralized material 1 | US$/t mined 2 |

| Open pit mining3 | 2.90 | 2.23 |

| Crushing 4 | 0.52 | 0.40 |

| Processing | 2.29 | 1.76 |

| G&A | 0.32 | 0.25 |

| Contingency (20%) 5 | 0.63 | 0.48 |

| All-in OPEX | 6.66 | 5.13 |

Notes:

- “Mineralized Material” represents mined material estimated to generate positive cash flows

- “Mined” means total tonnes mined (mineralized + waste)

- Open pit mining cost is $2.00/t for waste and $2.30/t for mineralization. A cost of $0.30/t mineralization has been included in the base case mining cost for mineralization to account for a longer haulage route to the leach pads than to the waste dumps.

- Crushing costs are calculated per tonne of mineralized material to leach pad (or mined) assuming 30% of mineralized material is crushed (crushing unit cost is estimated at $1.74/t of crusher feed material)

- Contingency is applied to OPEX excluding mine contractor rates which are current

Mineral Resources

As part of the PEA an updated Cerro de Oro project Mineral Resource Estimate was completed to reflect a higher gold price of US$1,700/oz which is more reflective of the three-year trailing average price. This reflects a change in the “reasonable prospects for eventual economic extraction” due to the current market conditions. Other than the change to the gold price assumption, the remainder of the estimate methodology remain identical to that utilized in the previous NI 43-101 report “Mineral Resource Estimate for the Cerro de Oro Project” by Scott Zelligan, P.Geo dated November 16th, 2020 that is currently available on SEDAR. The block model was constrained using an economic pit shell at the updated gold price resulting in the new and current Mineral Resource estimate as presented in Table 4.

Table 4 – Cerro de Oro Project, Estimate of Mineral Resources

| Resource Category | Material Type | Tonnes (t) | Au (g/t) | Au (oz) |

|---|---|---|---|---|

| Inferred | Oxide | 67,000,000 | 0.37 | 790,000 |

Notes:

- The independent and QP for the mineral resource estimates, as defined by NI 43‑101, is Scott Zelligan, P.Geo. The effective date of the 2022 mineral resource estimate is September 28, 2022.

- A gold price of $1,700/oz was used in calculating the Mineral Resources.

- The estimate is reported for a potential open pit/heap leach scenario.

- The limits of the Resource-constraining pit shell assumed a mining cut-off based on a total operating cost (mining, milling, and general and administrative [G&A]) of $8.80/t stacked, a metallurgical recovery of 70%, and a constant open pit slope angle of 45°. Inferred resources are too speculative geologically to have economic considerations applied to them.

- The gold cut-off grade applied to oxide mineralized material is 0.15 g/t Au

- These Mineral Resources are not Mineral Reserves as they do not have demonstrated economic viability.

- The Mineral Resource estimate follows CIM Definition Standards.

- Results are presented in-situ. Ounce (troy) = metric tonnes x grade / 31.103. Calculations used metric units (metres, tonnes, g/t). Rounding followed the recommendations as per NI 43‑101.

- The number of tonnes has been rounded to the nearest million.

- The QPs of this Report are not aware of any known environmental, permitting, legal, title-related, taxation, socio-political, marketing, or other relevant issues that could materially affect the Mineral Resource estimate other than those disclosed in this NI 43-101 compliant Technical Report.

The Mineral Resource estimate has been wholly classified as Inferred. The estimate represents the oxidized portion of the Cerro de Oro deposit. Although drill spacing is locally sufficient for Indicated classification, there remain necessary revisions and updates to the geological logs; better definition of the limit between the oxides and fresh rock; understanding of mineralization controls; and bulk density measurements. The reported inferred resources are estimated with an average drilling grid of approximately 85m by 85m.

Table 5 shows the open pit constrained Mineral Resource sensitivity to the gold price. The reader should be cautioned that the figures provided in Table 5 should not be interpreted as a Mineral Resource statement. The reported quantities and grade estimates at different gold prices are presented for the sole purpose of demonstrating the sensitivity of the resource model to the selection of a reporting gold price. The gold price of $1,700/oz that was used to report the Mineral Resources (the base case) for Cerro de Oro is highlighted in bold. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

Table 5 – Sensitivity of Mineral Resource to Gold Price

| Gold Price ($/oz) | Category | Tonnes (Mt) | Gold Grade (g/t) | Contained Ounces (‘000s) |

|---|---|---|---|---|

| 1,500 | Inferred | 54 | 0.40 | 690 |

| 1,600 | Inferred | 60 | 0.38 | 740 |

| 1,700 | Inferred | 67 | 0.37 | 790 |

| 1,800 | Inferred | 73 | 0.36 | 833 |

| 1,900 | Inferred | 78 | 0.35 | 865 |

Note: Mineral Resource is shown in bold.

Mining

The Cerro de Oro Project is planned as a conventional open pit operation that will utilize 100-t haul trucks and front-end loaders. Material will be drilled and blasted, before being loaded and hauled to a waste dump, crusher, or direct to the heap leach pad. Mining activities will be completed by a contractor who will supply all of the required mine equipment and personnel working under the supervision of the Company’s technical staff.

Using a nested pit shell that is based on a gold price of $1,500/oz and the economic parameters applied to the resource estimate as a guide, a full open pit mine plan was completed. Upon completion of the ultimate pit designs a check was completed that considered both revisions to the Company’s gold price forecast and its operating cost estimates for the Project. A LOM gold price of $1600/oz was selected for use in the final mine planning economics. Based on available metallurgical data for the project and an evaluation of the host rock lithologies it was assumed that the majority of mineralization mined will be placed directly on the heap leach as run-of-mine (“ROM”) with approximately 30% of the mineralization reporting to the crusher for size reduction (equivalent to crushing cut-off grade of approximately 0.40-0.45 g/t Au).

The mine production schedule anticipates that mining starts at the beginning of year 1 following the completion of all required earthworks activities such as road, dump and starter leach pad construction. Due to the low LOM strip ratio (0.30:1) and the size of the mineralization the PEA did not adjust the planned mining physicals to account for mining losses or dilution (magnitude of losses likely similar to dilution). Mine planning efforts going forward will be aimed at cut-off grades and the smoothing of the mining activities later in the mine life that may provide additional economic upside for the project. Over the life of mine of 8.2 years a total of 59Mt of mineralization grading 0.37 g/t gold (~700koz of contained gold) are anticipated to be mined.

Table 6 – Cerro de Oro Mine Production Schedule

| Year | Total Processed (tonnes) | Processed Head Grade Au (g/t) | Contained Gold (ounces) | Total Mined Material (tonnes) | Strip Ratio (Waste t: Mineral t) |

|---|---|---|---|---|---|

| 1 | 6,540,000 | 0.44 | 93,400 | 7,230,000 | 0.11 |

| 2 | 6,650,000 | 0.41 | 87,300 | 8,500,000 | 0.28 |

| 3 | 7,500,000 | 0.41 | 99,000 | 10,000,000 | 0.33 |

| 4 | 7,510,000 | 0.42 | 100,800 | 10,730,000 | 0.43 |

| 5 | 7,200,000 | 0.32 | 73,800 | 10,500,000 | 0.46 |

| 6 | 7,740,000 | 0.37 | 91,300 | 10,520,000 | 0.36 |

| 7 | 7,500,000 | 0.32 | 76,900 | 10,740,000 | 0.43 |

| 8 | 7,500,000 | 0.27 | 65,000 | 7,800,000 | 0.04 |

| 9 | 1,160,000 | 0.36 | 13,400 | 1,160,000 | – |

| 59,300,000 | 0.37 | 700,900 | 77,180,000 | 0.30 |

Notes:

- Processed totals include mineralization sent direct to the leach pad (41.5 million tonnes) and material sent to the crusher before stacking on the heap leach pad (17.8 million tonnes).

- Total mined material values include all production from the open pit mine (mineralization + waste) for noted intervals.

Pit bench heights were selected at 5m intervals in order to provide good ore/waste selectivity although use of larger bench heights in zones of primarily waste and on final open pit walls should be considered as part of future optimization studies. Overall average pit slopes with the benches/ramps in place range between approximately 30-43 degrees in the north pit and 34 – 38 degrees in the south pit.

It is assumed that all drilling/blasting/loading/hauling operations at the Project are planned to be completed via an open pit mining contractor. Mining costs were developed for the project utilizing recent Mexican cost information for similar heap leach operations and as part of the Company’s recent work at its Santana mine. Contractor availability in northern Mexico is currently high and rates are competitive. An additional cost was applied to the mineralized material to account on average for longer hauls to the heap leach pads over the mine life. Mine planning and supervision activities will be performed by Company personnel and these costs are excluded from contractor rates.

Processing

The process flowsheet for the Cerro de Oro project is similar to that utilized by the Company at their recently constructed Santana gold heap leach project. Metallurgical testwork completed to date on samples from the Cerro de Oro deposit indicate that the gold mineralization is well disseminated throughout the host rock and that the oxide mineralization responds positively to cyanidation. Residual gold contents following leaching in multiple series of bottle roll tests (conventional and coarse particle) appear to trend towards a typical range of ultimate values near 0.10 g/t Au. Leach kinetics were generally rapid in nature with low to moderate reagent consumptions (lime and cyanide). A limited number of column tests have been completed resulting in leach extractions consistent with those observed from bottle roll studies. Additional studies have been recommended to better define leaching parameters and any variability that may exist between the different mineralized zones and lithologies.

The process design for the Cerro de Oro gold project includes crushing of high grade material to less than 3/4-7/8” (30-35% of total with remaining low grade sent to leach pad as run-of-mine), a heap leaching pad, solution ponds and carbon column recovery of gold from pregnant leach solutions. The current design excludes carbon desorption and gold refining facilities as gold-loaded carbon will be shipped off-site for final dore production. The overall plant design was based on a nominal rate of 7,000,000 tonnes per year of mineralized material stacked to the leach pad at an average grade of 0.4 g/t Au. Sufficient excess capacity is included in the design to allow for expected annual variations in mine production around these nominal values. Base case leach solution flow rate to the carbon column recovery area was set at 800 m3/h with allowances to expand to 1,200 m3/h to accommodate increases in annual production rates and/or an expansion in the overall project resources.

The overall Cerro de Oro gold recovery facilities consist of the following unit operations and support facilities:

- Low grade run-of-mine material leach pad loading via direct truck dump

- Two stage crushing (jaw and cone) and screening operations for higher grade mine material with conveyor/stacker transport to leach pad

- Lined heap leach pad area sufficient to handle current life-of-mine resource (40-50% constructed initially as Phase 1 with subsequent expansions)

- Lined leach solution ponds adjacent to the leach pad – barren, pregnant and emergency overflow solution capacity

- Four trains of 4 stage carbon in columns with area to expand to six trains

- All required process pumping and loaded and barren carbon handling

- Reagent preparation and storage facilities

- Metallurgical laboratory (necessary production samples only)

- Utilities including water supply system (surface wells) and diesel power generation

Infrastructure

Access

The Cerro de Oro Project is accessible by road from the city of Saltillo in neighbouring Coahuila State, a driving distance of approximately 165 km, about a two-hour drive. The exit to Melchor Ocampo is off Federal Highway 54 approximately 5 km northeast of the town of Concepción del Oro. The site access road is approximately 2.5 km east of Melchor Ocampo, and itself is a 3 km gravel road that provides access to the Project site. All roads to the town are paved and in good condition.

Based on preliminary engineering a total of approximately 11km of new access roads are required for initial site development and early mine production. Roads will consist of gravel surface suitable for the operation of mining trucks and general purpose vehicles. An allowance has also been included for some upgrading of existing roads including the widening of sections that pass through/near the project mining operations in order to better accommodate two-way truck traffic

Power

Details of the complete modifications to the existing crushing system previously purchased by the company have not yet been completed but the arrangement will include a truck dump hopper/feeder, two stage crushing and screening as well as required transfer conveyors and area sufficient for short term material stockpiles. It is planned that “grasshopper” style conveyors will be utilized to transfer crushed rock to a mobile stacker located at the leach pad for final stacking/placement. In total an allowance has been included for a connected load of approximately 1.5 MW to power all the major crusher and transfer equipment unit operations. An existing 2MW backup diesel generator was acquired as part of the overall used crushing circuit equipment and will be installed as a backup.

The nearest federal electricity (“CFE”) connection to the planned crushing area is a local line approximately 0.5 km to the east. The main line supplying the town of Melchor Ocampo runs along the primary access road to the town approximately 2 km to the south. The company is currently discussing the project requirements with the CFE to confirm sufficient capacity exists within the local network and to confirm acceptable locations for connection to the power grid.

It is assumed for the foreseeable future that all power required for the Cerro de Oro gold leaching and recovery plant operations will be generated at site via diesel generators. The total maximum operating plant power load is estimated at 780 kW (actual draw will vary over LOM and as leach pad evolves) which will be supplied via a single diesel generator unit (1 MW). A backup generator (300-400 kW) will also be installed to manage basic requirements during maintenance periods or periods of reduced solution pumping. Generators are to be located within close proximity to the processing plant area, so transmission line requirements will be negligible. Wherever possible, smaller power consumers not associated with the processing plant (i.e., test wells, local offices) will be self-contained with local diesel hydraulic/electric generation.

At current fuel prices in Mexico diesel generation is equivalent to an electric power cost in the range of $0.30/kWh, which has been used for budgeting purposes in the PEA. Should the project resources continue to grow further studies would be warranted to investigate the economics of extending grid power to the process plan area.

Water Management

The sources of process water available for the Cerro de Oro project consist of groundwater wells. In mid 2022, a hydrogeological consulting group was retained by the Company to perform reviews of the Cerro de Oro area and to better understand the regional water flows around Melchor Ocampo. A series of reconnaissance visits were completed to review available regional geology maps for the area and to make local field investigations (including electromagnetic geophysical surveys – TEM). Seven (7) high priority targets have been selected by the company for test drilling down to a maximum depth of 300 meters. The majority of the target areas are located north of the planned leach pad/processing plant facilities and at a distance of less than 5km.

Other Infrastructure

Preliminary estimates were completed to calculate the total amount of material to be excavated during the overall site preparations. Of this total approximately 40% will be moved short distances and utilized as compacted fill. The remainder will be moved to one of the site waste storage dumps.

Other general infrastructure to be constructed at the project includes offices, powder magazines, lab and warehouse facilities. No capital allowance has been made for the truck shop area as these facilities are typically provided by the mine contractor as part of the contract for mining operations. Simple buildings are planned with a combination of trailers/container units and locally constructed concrete block structures. Only very basic lab services are planned for the site focusing exclusively on production samples (mine blastholes and process solutions). Other samples/testwork/analysis to be completed for the project will be completed at third party facilities located in Zacatecas or Durango.

General Administration

The PEA model is based on the assumption that Minera Alamos will provide overall site management, technical support and surface and processing plant personnel. Mining and crushing activities will be completed by contractors and all personnel other than high level supervision and planning are included in the contractor costs.

It is anticipated that wherever possible basic operations labour will be sourced locally from the Melchor Ocampo area or other small nearby villages. Management and more skilled personnel that are not locally available can be sourced from the Concepcion de Oro general area which is a local center for a number of mining operations. Minera Alamos will provide basic transportation services (by road) for operations personnel.

Minera Alamos plans to maintain a local operations office in Melchor Ocampo and will have some accommodation facilities in the town that can be utilized by visiting management personnel and outside consultants.

Permitting Status

No permits have been granted for the development of the Cerro de Oro Project. The Company intends to advance efforts related to the application for these documents prior to a decision being made to develop the Project. The primary applications under consideration include:

- Environmental Impact Statement (Manifestación de Impacto Ambiental or MIA)

- Technical Justification Study (Estudio Técnico Justificativo or ETJ) which includes the Change of Land Use (Cambio de Uso de Suelo or CUS)

When appropriate, the Company will submit these applications to the appropriate government agencies, including the Secretariat of Environment and Natural Resources (SEMARNAT).

A prerequisite for these submissions is the completion of a surface agreement(s) that covers the development areas of interest. Agreements were finalized by the company in 2022 and work is currently underway to prepare the MIA/ETJ application documents. In total the Company is in possession of two surface rights rental agreements covering a period of 25 years – 656 Ha from the Melchor Ocampo municipality and an adjacent 160 Ha from the local Ejido.

Following the completion of the ETJ/MIA process a number of other registrations and local/state permits are required in advance of various site development stages and the start of commercial production. These include:

- “Water Use” – Comisión de Agua (National Water Commission or CONAGUA). The company initiated the hydrogeological studies required for this permit in 2022

- “Explosives Use” – Covers projected explosives requirements and design of explosives storage facilities.

- “Exploration Permits” – As required when surface disturbances are created for site drilling purposes.

- “Construction Permits” – Obtained from the local municipality.

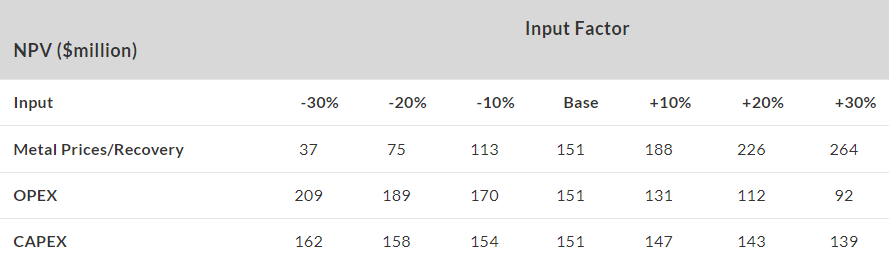

Sensitivity Analysis

A sensitivity analysis was conducted on the base case (after-tax) NPV for the Project using the following variables – metal price/recovery, initial CAPEX and total OPEX. Table 7 and Figure 1 summarize the sensitivity analysis results. As illustrated the Project NPV is most sensitive to changes in metal price/recovery and less sensitive to initial CAPEX and OPEX.

Table 7 – Sensitivity Analysis (5% discount / after-tax)

Project Opportunities

The PEA identifies several project opportunities to further enhance project economics. These include:

- The known zones of gold mineralization appear to remain open both laterally and at depth.

- Additional metallurgical testwork should allow for a more complete understanding of the gold recovery versus crush size relationships for different areas of the deposit and potential improvements in overall gold extraction via optimization of the processing parameters

- Based on preliminary testwork there appears to be potential to leach sulphide mineralization at depth. Further metallurgical work should continue to evaluate the amenability of leaching this material, followed by additional drilling to better delineate the extents of these zones if warranted.

- Additional mine planning optimization studies to evaluate opportunities to expand annual production rates and better optimize production phasing.

- Haul road optimization to attempt to reduce distances to the planned leach pads

Project Recommendations

The PEA identifies several recommendations to advance the development of the Project. These include:

- Topographic work to provide additional accurate positions and directional details for historical drill holes.

- Infill drilling program (Phase 1) for resource modelling purposes and to collect samples for additional metallurgical test work as well as in-situ rock density studies.

- Preparation of plans for an additional phase of exploration drilling aimed at defining disseminated sulphide extensions of known oxide mineralization.

- Geotechnical site investigations to obtain a better understanding of existing ground conditions for open pit slope, waste dump and leach pad design purposes.

- Further pit design optimization to examine access road development alternatives, open pit phasing to maximize mined mineralization release and further smoothing of the production profile later in the mine life.

- Additional metallurgical optimization studies (coarse bottle roll and columns) to examine crush size/gold recovery relationships and variability for primary lithological zones within the Project mineralization.

- Sulphide mineralization leach studies.

- Complete environmental baseline studies for preparation of MIA/ETJ application.

- Hydrogeological survey of the project area to prioritize locations for process water access.

Qualified Person Statements

The 2022 PEA was conducted by the following Qualified Persons contributing to their respective sections. All Qualified Persons (“QPs”) as defined under Canadian National Instrument 43-101. All of the QPs are “independent” of the Company pursuant to National Instrument 43-101. The listed Qualified Persons have reviewed the data contained in this news release and verified that it is accurately disclosed.

| Scott Zelligan | P.Geo., Independent Resource Geologist |

|---|---|

| Lawrence Segerstrom | M. Sc. (Geology), CPG |

| Peimeng, Ling | P.Eng. |

| Alex Duggan | P.Eng. |

| Toren Olson | PG |

Mr. Darren Koningen, P.Eng, a ‘Qualified Person’ as defined under Canadian National Instrument 43‑101, is responsible for the other technical information (information not directly related to the PEA) in this news release.

For Further Information Please Contact:

Minera Alamos Inc.

Doug Ramshaw, President

Tel: 604-600-4423

Email: dramshaw@mineraalamos.com

Victoria Vargas de Szarzynski, VP Investor Relations

Tel: 289-242-3599

Email: vvargas@mineraalamos.com

Website: www.mineraalamos.com

About Minera Alamos Inc.

Minera Alamos is a gold production and development Company undergoing the operational startup of its first gold mine that produced its first gold in October 2021. The Company has a portfolio of high-quality Mexican assets, including the 100%-owned Santana open-pit, heap-leach mine in Sonora that is currently going through its operational ramp up. The 100%-owned Cerro de Oro oxide gold project in northern Zacatecas that has considerable past drilling and metallurgical work completed with plans to enter the permitting process. The La Fortuna open pit gold project in Durango (100%-owned) has an robust and positive preliminary economic assessment (PEA) completed and the main Federal permits in hand. Minera Alamos is built around its operating team that together brought 3 mines into successful production in Mexico over the last 13 years.

The Company’s strategy is to develop very low capex assets while expanding the projects’ resources and continuing to pursue complementary strategic acquisitions.

NON-GAAP Financial Performance Measures

The Company has included certain non-GAAP performance measures (All-in Sustaining Cost – “AISC”) in this document. The Company believes that, in addition to conventional measures prepared in accordance with GAAP, certain investors and other stakeholders also use this information to evaluate the Company’s economic performance estimates; however, these non-GAAP performance measures do not have any standardized meaning. Accordingly, these performance measures are intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with GAAP. The Company’s primary business is gold asset development and maximizing returns from future gold production, with other metal production being incidental to the gold production process. As a result, where applicable, the Company’s non-GAAP performance measures are disclosed on a per gold ounce basis. The Company has followed the guidance note released by the World Gold Council, which became effective January 1, 2014. The World Gold Council is a non-regulatory market development organization for the gold industry whose members comprise global senior gold mining companies.

Caution Regarding Forward-Looking Statements

This news release may contain forward-looking information and Minera Alamos cautions readers that forward-looking information is based on certain assumptions and risk factors that could cause actual results to differ materially from the expectations of Minera Alamos included in this news release. This news release includes certain “forward-looking statements”, which often, but not always, can be identified by the use of words such as “believes”, “anticipates”, “expects”, “estimates”, “may”, “could”, “would”, “will”, or “plan”. These statements are based on information currently available to Minera Alamos and Minera Alamos provides no assurance that actual results will meet management’s expectations. Forward-looking statements include estimates and statements with respect to Minera Alamos’ future plans with respect to the Projects, objectives or goals, to the effect that Minera Alamos or management expects a stated condition or result to occur and the expected timing for release of a resource and reserve estimate on the projects. Since forward-looking statements are based on assumptions and address future events and conditions, by their very nature they involve inherent risks and uncertainties. Actual results relating to, among other things, results of exploration, the economics of processing methods, project development, reclamation and capital costs of Minera Alamos’ mineral properties, the ability to complete a preliminary economic assessment which supports the technical and economic viability of mineral production could differ materially from those currently anticipated in such statements for many reasons. Minera Alamos’ financial condition and prospects could differ materially from those currently anticipated in such statements for many reasons such as: an inability to finance and/or complete an updated resource and reserve estimate and a preliminary economic assessment which supports the technical and economic viability of mineral production; changes in general economic conditions and conditions in the financial markets; changes in demand and prices for minerals; litigation, legislative, environmental and other judicial, regulatory, political and competitive developments; technological and operational difficulties encountered in connection with Minera Alamos’ activities; and other matters discussed in this news release and in filings made with securities regulators. This list is not exhaustive of the factors that may affect any of Minera Alamos’ forward-looking statements. These and other factors should be considered carefully and readers should not place undue reliance on Minera Alamos’ forward-looking statements. Minera Alamos does not undertake to update any forward-looking statement that may be made from time to time by Minera Alamos or on its behalf, except in accordance with applicable securities laws.

The Company does not have a feasibility study of mineral reserves, demonstrating economic and technical viability for the Santana project, and, as a result, there may be an increased uncertainty of achieving any particular level of recovery of minerals or the cost of such recovery, including increased risks associated with developing a commercially mineable deposit. Historically, such projects have a much higher risk of economic and technical failure. Failure to commence production would have a material adverse impact on the Company’s ability to generate revenue and cash flow to fund operations.

NEITHER TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

Original Article: https://mineraalamos.com/news/2022/minera-alamos-announces-positive-preliminary-economic-assessment-for-the-cerro-de-oro-gold-project/