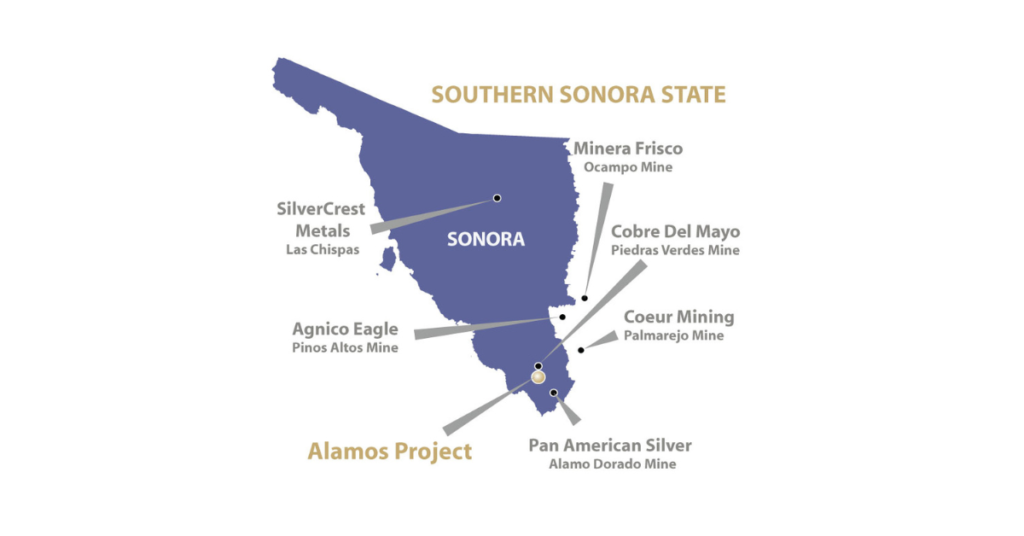

Vancouver, British Columbia–(Newsfile Corp. – November 15, 2022) – Minaurum Gold, Inc (TSXV: MGG) (OTCQX: MMRGF) (“Minaurum”) is pleased to provide an update on the underground rehabilitation work at the historical Promontorio mine, located in its flagship 100%-owned Alamos silver project in Sonora, Mexico. Minaurum has successfully accessed and is dewatering the main haulage level along with clearing crosscuts in the El Tirito area of the mine. This led to the discovery of several historical underground drill collars, confirming historical reports from the 1960s. Five service holes were drilled to provide air, water, and electricity to facilitate underground rehabilitation efforts. Three of the service holes intercepted the Promontorio vein at its highest levels returning high-grade base metal mineralization including 5.8 m of 98 g/t Ag, 3.6% Pb, and 7.9% Zn.

Sampling and mapping of dumps at Promontorio revealed a boulder of massive sulfide vein assaying 3,320 g/t Ag, 54.7 g/t Au, 25% Cu, 6.5% Pb, and 1.1% Zn. The boulder, measuring roughly a meter across, is an indication of the type of grades exploited by early miners at Promontorio.

“Confirming the location of the 1960s drill collars and finding discarded high-grade vein material were welcome bonuses to regaining underground access for mapping and sampling,” stated Darrell Rader, Minaurum Gold President and CEO. “Getting underground where no one has been for decades allows us to improve our geological understanding of the silver shoots in the district and provides the ability to commence underground drilling.”

Promontorio Rehabilitation

The workings are in good condition. Rehabilitation and exploration work efforts are focusing first in the El Tirito shaft area, which lies approximately 300 m from the Promontorio adit entrance. Crews are clearing and stabilizing cross cuts and stopes, including access to the internal shaft. Activities completed include timbering and shoring up the adit entrance, preparing a staging area outside the adit entrance, cleaning out and stabilizing the adit, and draining water from the main haulage level. Approximately 200 tonnes of ballast and 50 tonnes of backfill have been removed from the first 300 m of the haulage level and stockpiled outside the mine entrance. Sampling results will be released shortly.

Historical Data Validation & Minaurum Drilling Confirm Mineralization Continues

Drill steel marking the collar locations of three historical holes (U-7, U-8, and U-9) was located approximately 250 m into the main haulage level, confirming historical data. Two of the holes returned 2.7 m of 274 g/t silver (Hole U-7, approximately 30 m below haulage level), and 2.1 m of 247 g/t silver (Hole U-8, approximately 50 m below haulage level). No assay information is available for Hole U-9 (Figure 1)(see Minaurum Historical Data news release dated February 6, 2020). The relationship of the reported intercept of Hole U-7 to the historical drilling and workings, as well as to Minaurum’s drilling, confirm the general model of a NNE-trending, steeply WNW-dipping vein zone. Hole U-8’s intercept appears to confirm mineralization in a NW-trending fault. Based on both sets of drill holes, potential for high-grade silver mineralization at depth at the lower levels, and on the southwest side, down-dropped side of the northwest-trending fault exists.

Figure 1. Close-up plan view of drill intercepts around El Tirito area at Promontorio mine. Note mineralized intercepts on southwest (down-thrown) side of northwest-trending fault.

Click image to enlarge.

To view an enhanced version of Figure 1, please visit:

https://images.newsfilecorp.com/files/3455/143988_ff155885547f8b9a_003full.jpg

Five service holes were drilled to provide electricity and air to the underground workings. Two of the service holes were in the El Tirito area and three were drilled in the Balvanera area (Table 1). The three parallel service holes drilled at the Balvanera area are separated by less than 2 metres. Each drilled a high-level mineralized vein/fault zone from approximately 93 to 99 m. The relationship of the service holes to previous drilling is shown in Figure 2. Mineralized intercepts in the service holes confirm the continuity of the vein zone and variability of grade and thickness along it; intersecting high-grade base metals of 7.9% zinc, 3.6% lead, 0.34% copper and 0.48 g/t gold (Hole AL22-100) and 5.5% zinc, 3.1% lead, and 0.24% copper (Hole AL22-101) (Table 1 and Figure 2).

Table 1. Weight-averaged grades from service holes drilled in the Balvanera area.

| HoleID | From | To | Interval | Ag g/t | Au g/t | Cu % | Pb % | Zn % |

| AL22-100 | 93.30 | 99.10 | 5.80 | 98 | 0.487 | 0.339 | 3.621 | 7.908 |

| AL22-101 | 92.80 | 99.20 | 6.40 | 72 | 0.225 | 0.246 | 3.095 | 5.566 |

| AL22-102 | 95.50 | 98.90 | 3.40 | 41 | 0.235 | 0.120 | 1.576 | 5.863 |

Figure 2. Cross section showing relationship of service holes AL22-100, -101, and -102 to previous holes AL17-004 and -005. Balvanera area.

Click image to enlarge.

To view an enhanced version of Figure 2, please visit:

https://images.newsfilecorp.com/files/3455/143988_ff155885547f8b9a_004full.jpg

Minaurum Gold Inc. (TSXV: MGG) (OTCQX: MMRGF) (FSE: 78M) is a Mexico-focused explorer concentrating on the high-grade Alamos silver project in southern Sonora. With a property portfolio encompassing multiple additional district-scale projects, Minaurum is managed by one of the strongest technical and finance teams in Mexico. Minaurum’s goal is to continue its founders’ legacy of creating shareholder value by making district-scale mineral discoveries and executing accretive mining transactions. For more information, please visit our website at www.minaurum.com and follow us on YouTube, Twitter and LinkedIn.

ON BEHALF OF THE BOARD

“Darrell A. Rader“

Darrell A. Rader

President and CEO

For more information, please contact:

Sunny Pannu – Investor Relations and Corporate Development Manager

(778) 330 0994 or via email at pannu@minaurum.com

The TSX Venture Exchange does not accept responsibility for the adequacy or accuracy of this news release.

___________________________________________________________________________

2710 – 200 Granville Street

Vancouver, BC V6C 1S4

Telephone 778 330-0994

www.minaurum.com

info@minaurum.com

Stephen R. Maynard, Vice President of Exploration of Minaurum and a Qualified Person as defined by National Instrument 43-101, reviewed and verified the assay data, and has approved the disclosure in this News Release. Historical data reported in this news release has not been verified.

Cautionary Note Regarding Forward-Looking Statements: Certain disclosures in this release constitute forward-looking information. In making the forward-looking statements in this release, Minaurum has applied certain factors and assumptions that are based on Minaurum’ s current beliefs as well as assumptions made by and information currently available to Minaurum. Although Minaurum considers these assumptions to be reasonable based on information currently available to it, they may prove to be incorrect, and the forward-looking statements in this release are subject to numerous risks, uncertainties and other factors that may cause future results to differ materially from those expressed or implied in such forward-looking statements. Readers are cautioned not to place undue reliance on forward-looking statements. Minaurum does not intend, and expressly disclaims any intention or obligation to, update or revise any forward-looking statements whether as a result of new information, future events or otherwise, except as required by law.

Quality Assurance/Quality Control: Preparation and assaying of drilling samples from Minaurum’s Alamos project are done with strict adherence to a Quality Assurance/Quality Control (QA/QC) protocol. Core samples are sawed in half and then bagged in a secure facility near the site, and then shipped by a licensed courier to ALS Minerals’ preparation facility in Hermosillo, Sonora, Mexico. ALS prepares the samples, crushing them to 70% less than 2mm, splitting off 250g, and pulverizing the split to more than 85% passing 75 microns. The resulting sample pulps are prepared in Hermosillo, and then shipped to Vancouver for chemical analysis by ALS Minerals. In Vancouver, the pulps are analyzed for gold by fire assay and ICP/AES on a 50-gram charge. In addition, analyses are done for a 48- element suite using 4-acid digestion and ICP analysis. Samples with silver values greater than 100 g/t; and copper, lead, or zinc values greater than 10,000 ppm (1%) are re-analyzed using 4-acid digestion and atomic absorption spectrometry (AAS).

Quality-control (QC) samples are inserted in the sample stream every 20 samples, and thus represent 5% of the total samples. QC samples include standards, blanks, and duplicate samples. Standards are pulps that have been prepared by a third-party laboratory; they have gold, silver, and base-metal values that are established by an extensive analytical process in which several commercial labs (including ALS Minerals) participate. Standards test the calibration of the analytical equipment. Blanks are rock material known from prior sampling to contain less than 0.005 ppm gold; they test the sample preparation procedure for cross-sample contamination. In the case of duplicates, the sample interval is cut in half, and then quartered. The first quarter is the original sample, the second becomes the duplicate. Duplicate samples provide a test of the reproducibility of assays in the same drilled interval. When final assays are received, QC sample results are inspected for deviation from accepted values. To date, QC sample analytical results have fallen in acceptable ranges on the Alamos project.

Original Article: https://www.newsfilecorp.com/release/143988