(All amounts expressed in U.S. dollars unless otherwise noted)

TORONTO, July 31, 2024 /PRNewswire/ – Agnico Eagle Mines Limited (NYSE: AEM) (TSX: AEM) (“Agnico Eagle” or the “Company”) today reported financial and operating results for the second quarter of 2024.

“We continue to deliver strong and reliable operational results which, combined with higher gold prices, drove record operating margin and free cash flow for the third consecutive quarter. As a result of the excellent performance of our operations through the first half of 2024, we are highly confident we will achieve our full year production and cost guidance,” said Ammar Al-Joundi, Agnico Eagle’s President and Chief Executive Officer. “We generated over half of a billion dollars of free cash flow in the second quarter, supporting a significant strengthening of our balance sheet and increased returns to shareholders. We continue to take a measured approach advancing key pipeline projects that show strong risk-adjusted returns, such as the Detour Lake underground and Upper Beaver projects. Our focus remains on capital discipline and cost control to ensure that the benefits of higher gold prices accrue to our shareholders through strengthening our financial position and increasing shareholder returns,” added Mr. Al-Joundi.

Second quarter 2024 highlights:

- Strong quarterly gold production – Payable gold production1 was 895,838 ounces at production costs per ounce of $862, total cash costs per ounce2 of $870 and all-in sustaining costs (“AISC”) per ounce2 of $1,169. Gold production was led by strong production at Canadian Malartic, LaRonde and Fosterville

- Record quarterly adjusted net income3 – The Company reported quarterly net income of $472.0 million or $0.95 per share and adjusted net income of $535.3 million or $1.07 per share

- Record quarterly cash provided by operating activities and free cash flow – The Company generated record cash provided by operating activities of $961.3 million or $1.92 per share ($986.2 million or $1.97 per share before changes in non-cash working capital balances4) and free cash flow4 of $557.2 million or $1.12 per share ($582.2 million or $1.17 per share before changes in non-cash working capital balances4)

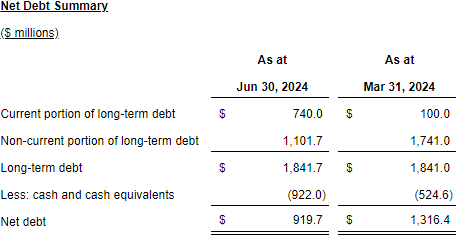

- Strengthening investment grade balance sheet and financial flexibility – The Company increased its cash position by $397.4 million to $922.0 million and significantly reduced net debt as at June 30, 2024. Subsequent to quarter-end, the Company repaid the $100.0 million 5.02% Series B senior notes at maturity and repaid $150.0 million of the $600.0 million unsecured term loan facility drawn in 2023

- 2024 gold production and cost guidance reiterated – Full year expected payable gold production remains unchanged at approximately 3.35 to 3.55 million ounces in 2024, with total cash costs per ounce and AISC per ounce in 2024 unchanged at $875 to $925 and $1,200 to $1,250, respectively. Total capital expenditures (excluding capitalized exploration) for 2024 are still estimated to be between $1.6 billion to $1.7 billion. Capitalized exploration is now expected to be approximately $187 million for the full year 2024. Further details are set out in the “2024 Guidance” section below

- Update on key value drivers and pipeline projects

- Approval of measured investments over next three years to further evaluate and de-risk the Detour Lake underground and Upper Beaver projects – Based on internal studies indicating solid risk-adjusted returns for the Detour Lake underground and Upper Beaver projects5, the Company has adopted a measured approach to advance these projects, approving $100.0 million and $200.0 million investments, respectively, over approximately three years. At Detour Lake, a 2.0-kilometre exploration ramp is expected to be developed to a depth of 270 metres to collect a bulk sample and to facilitate infill and expansion drilling of the current underground mineral resource. At Upper Beaver, an exploration ramp and an exploration shaft are expected to be developed to a depth of 250 metres and 760 metres, respectively, to establish underground drilling platforms and collect bulk samples

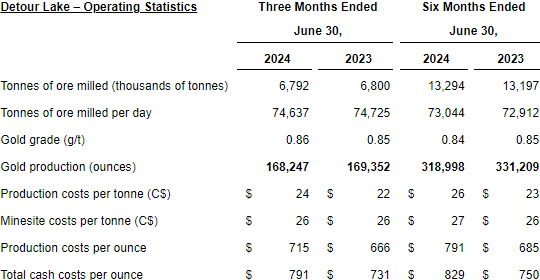

- Detour Lake – In June 2024, the Company released the results of a technical study reflecting the potential for a concurrent underground operation at Detour Lake that would accelerate access to higher grade ore and increase annual production to approximately one million ounces for 14 years starting in 2030 (see the Company’s news release dated June 19, 2024). In the second quarter of 2024, with the replacement of the defective grinding media at the SAG mill and record quarterly mill availability of 93.0%, mill throughput improved to 74,637 tonnes per day (“tpd”) and is expected to reach the target rate of 76,700 tpd by the end of 2024

- Upper Beaver – A positive internal evaluation was completed in June 2024 for a standalone mine and mill scenario at Upper Beaver. Based on this evaluation, the Company believes Upper Beaver has the potential to produce an annual average of approximately 210,000 ounces of gold and 3,600 tonnes of copper, with initial production possible as early as 2030. Over an expected 13-year mine life, total payable gold and copper production is expected to be approximately 2.8 million ounces and 46,300 tonnes, respectively. Estimated total cash costs per ounce on a by-product basis and AISC per ounce on a by-product basis are expected to be approximately $592 and $733, respectively. In addition, the project has the potential to unlock significant exploration potential at depth and within satellite deposits in the Company’s Kirkland Lake camp

- Odyssey mine at Canadian Malartic – At Odyssey South, record quarterly mining rates and gold production were achieved at approximately 3,750 tpd and 22,300 ounces of gold, respectively. In the second quarter of 2024, ramp development continued to exceed the Company’s target, reaching the third production level at East Gouldie at a depth of 832 metres as at June 30, 2024. Shaft sinking advanced at an average rate of 2.5 metres per day and reached a depth of 680 metres as at June 30, 2024. Surface construction is progressing as planned, with a focus on the main hoist building, phase two of the paste plant and the operations complex

- Approval of a supplemental exploration budget of $50.0 million – The Company’s exploration program returned positive results in the first half of 2024 at Canadian Malartic, Detour Lake and Hope Bay, showing excellent potential to identify additional mineral resources. These results support increased budgets approved by the Company for the second half of 2024.

- East Gouldie at Odyssey mine – Recent exploration drilling continued to return good results in the eastern and western extensions of the East Gouldie deposit including 4.5 grams per tonne (“g/t”) gold over 6.5 metres at 1,571 metres depth approximately 770 metres east of the current mineral reserves and 2.5 g/t gold over 30.0 metres at 1,473 metres depth and 85 metres west of the current mineral reserves. The results from the ongoing exploration program are anticipated to have a positive impact on the mineral resource estimate at year-end 2024

- Detour Lake underground – Infill drilling into the high-grade corridor in the West Pit zone continued to confirm the higher grades and mineralized structure amenable to underground mining. Highlights include 4.0 g/t gold over 22.3 metres at 413 metres depth and 4.4 g/t gold over 30.1 metres at 550 metres depth. Near the proposed exploration ramp, highlights include 20.6 g/t gold over 5.5 metres at 280 metres depth and 4.7 g/t gold over 15.6 metres at 313 metres depth

- Madrid at Hope Bay – Exploration drilling during the second quarter of 2024 totalled 35,400 metres and continued to return strong results from infill drilling north of the Patch 7 mineral resources, including 17.0 g/t gold over 25.8 metres at 419 metres depth, 7.2 g/t gold over 8.1 metres at 559 metres depth and 5.3 g/t gold over 18.0 metres at 278 metres depth, further confirming the greater thicknesses and higher gold grades in this area compared to the rest of the Madrid deposit

- Reconciliation Action Plan and 2023 Climate Action Report published – On July 10, 2024, the Company released its first Reconciliation Action Plan, reinforcing its commitment to reconciliation with Indigenous Peoples and communities. In addition, on July 31, 2024, the Company released its 2023 Climate Action Report. In line with the recommendations of the Task Force on Climate-related Financial Disclosures and Towards Sustainable Mining Climate Change protocol, the 2023 Climate Action Report outlines how the Company is addressing climate change risks and opportunities

- Continued focus on shareholder returns – In the second quarter of 2024, the board of directors declared a quarterly dividend of $0.40 per share. In the second quarter of 2024, the Company also repurchased 763,043 common shares at an average share price of $65.53 for an aggregate of $50.0 million through its normal course issuer bid (“NCIB”), which was renewed in May 2024

- Approval of measured investments over next three years to further evaluate and de-risk the Detour Lake underground and Upper Beaver projects – Based on internal studies indicating solid risk-adjusted returns for the Detour Lake underground and Upper Beaver projects5, the Company has adopted a measured approach to advance these projects, approving $100.0 million and $200.0 million investments, respectively, over approximately three years. At Detour Lake, a 2.0-kilometre exploration ramp is expected to be developed to a depth of 270 metres to collect a bulk sample and to facilitate infill and expansion drilling of the current underground mineral resource. At Upper Beaver, an exploration ramp and an exploration shaft are expected to be developed to a depth of 250 metres and 760 metres, respectively, to establish underground drilling platforms and collect bulk samples

1 Payable production of a mineral means the quantity of a mineral produced during a period contained in products that have been or will be sold by the Company whether such products are shipped during the period or held as inventory at the end of the period.

2 Total cash costs per ounce and AISC per ounce are a non-GAAP ratios that are not standardized financial measures under IFRS and, in this news release, unless otherwise specified, are reported on (i) a per ounce of gold production basis, and (ii) a by-product basis. For a description of the composition and usefulness of these non-GAAP measures and reconciliations of total cash costs per ounce and AISC per ounce to production costs on both a by-product and a co-product basis, see “Note Regarding Certain Measures of Performance” below.

3 Adjusted net income and adjusted net income per share are non-GAAP measures or ratios that are not standardized financial measures under IFRS. For a description of the composition and usefulness of these non-GAAP measures and a reconciliation to net income see “Note Regarding Certain Measures of Performance” below.

4 Cash provided by operating activities before changes in non-cash working capital balances, free cash flow and free cash flow before changes in non-cash working capital balances and their related per share measures are non-GAAP measures or ratios that are not standardized financial measures under IFRS. For a description of the composition and usefulness of these non-GAAP measures and a reconciliation to cash provided by operating activities see “Note Regarding Certain Measures of Performance” below.

5 The forecast parameters surrounding the technical study for the Detour Lake underground project and the internal evaluation for the Upper Beaver project were based on a preliminary economic assessment, which is preliminary in nature and includes inferred mineral resources. For further detail, refer to the Company’s news release dated June 19, 2024 for the Detour Lake underground project and the Update on Key Value Drivers and Pipeline Projects section set our below for the Upper Beaver project.

Second Quarter 2024 Results Conference Call and Webcast Tomorrow

Agnico Eagle’s senior management will host a conference call on Thursday, August 1, 2024 at 11:00 AM (E.D.T.) to discuss the Company’s financial and operating results.

Via Webcast:

To listen to the live webcast of the conference call, you may register on the Company website at www.agnicoeagle.com, or directly via the link here.

Via Phone:

To join the conference call by phone, please dial 416.764.8659 or toll-free 1.888.664.6392 to be entered into the call by an operator. To ensure your participation, please call approximately five minutes prior to the scheduled start of the call.

To join the conference call by phone without operator assistance, you may register your phone number here 30 minutes prior to the scheduled start of the call to receive an instant automated call back.

Replay Archive:

Please dial 416.764.8677 or toll-free 1.888.390.0541, access code 576159#. The conference call replay will expire on September 1, 2024.

The webcast, along with presentation slides, will be archived for 180 days on the Company’s website.

Second Quarter 2024 Production and Cost Results

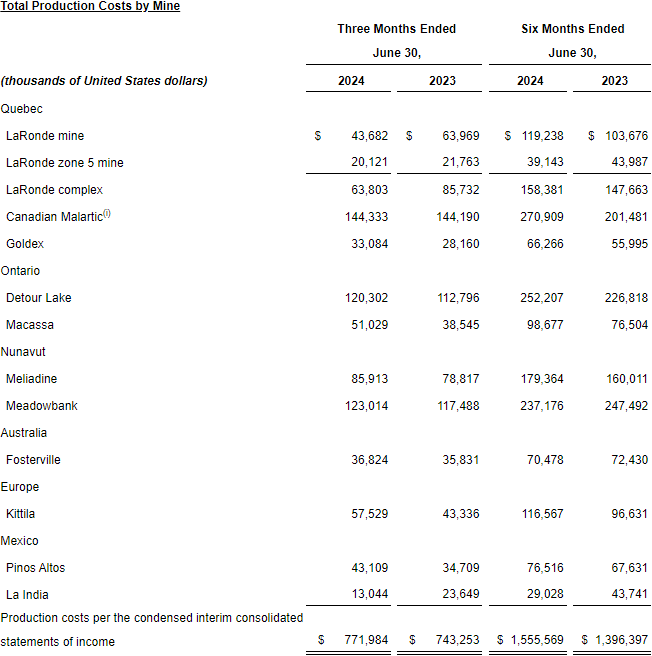

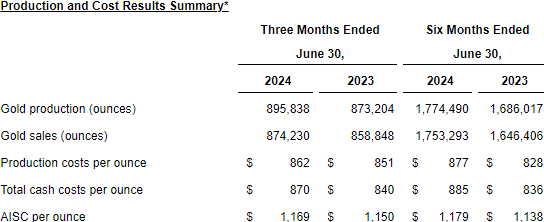

* Production and Cost Results Summary reflects Agnico Eagle’s 50% interest in Canadian Malartic up to and including March 30, 2023 and 100% thereafter.

Gold Production

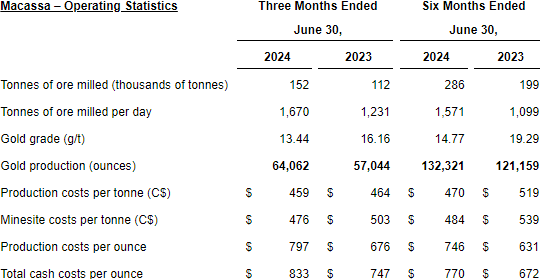

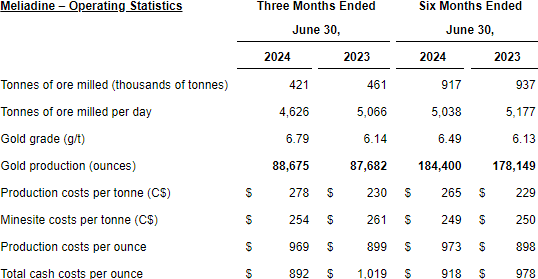

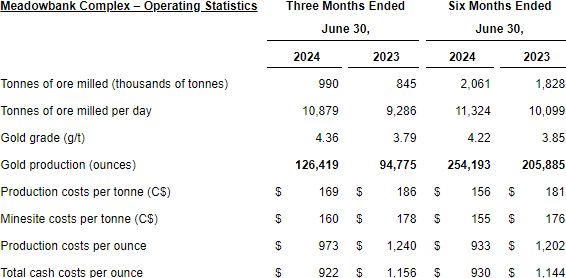

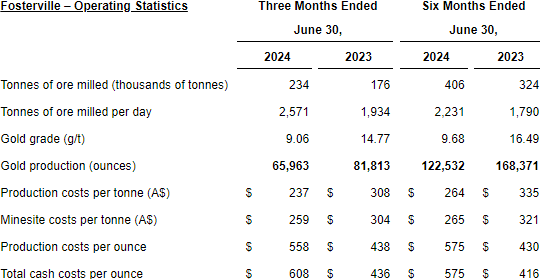

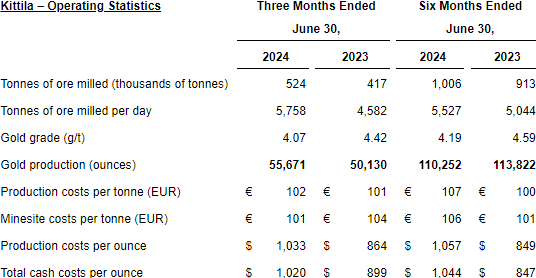

- Second Quarter of 2024 – Gold production increased when compared to the prior-year period primarily due to higher production from Meadowbank and Macassa, partially offset by lower production at Fosterville

- First Six Months of 2024 – Gold production increased when compared to the prior-year period as a result of the additional production from the acquisition of the remaining 50% of Canadian Malartic, contribution from Odyssey in the current year and increased production from Meadowbank, partially offset by lower production at Fosterville

Production Costs per Ounce

- Second Quarter and First Six Months of 2024 – Total production costs per ounce increased when compared to the prior-year periods primarily due to higher royalties mainly arising from higher gold prices and higher production costs at Canadian Malartic related to underground mining operations, partially offset by higher gold production during the period

Total Cash Costs per Ounce

- Second Quarter and First Six Months of 2024 – Total cash costs per ounce increased when compared to the prior-year periods primarily due to the reasons described above for the increase in production costs per ounce combined with the impact of lower gold grades at Fosterville, partially offset by higher gold production during the period

AISC per Ounce

- Second Quarter of 2024 – AISC per ounce increased when compared to the prior-year period due to the factors causing higher total cash costs per ounce, partially offset by higher production and slightly lower sustaining capital expenditures during the period

- First Six Months of 2024 – AISC per ounce increased when compared to the prior-year period due to the factors causing higher total cash costs per ounce and higher sustaining capital expenditures, partially offset by higher gold production during the period

Second Quarter 2024 Financial Results

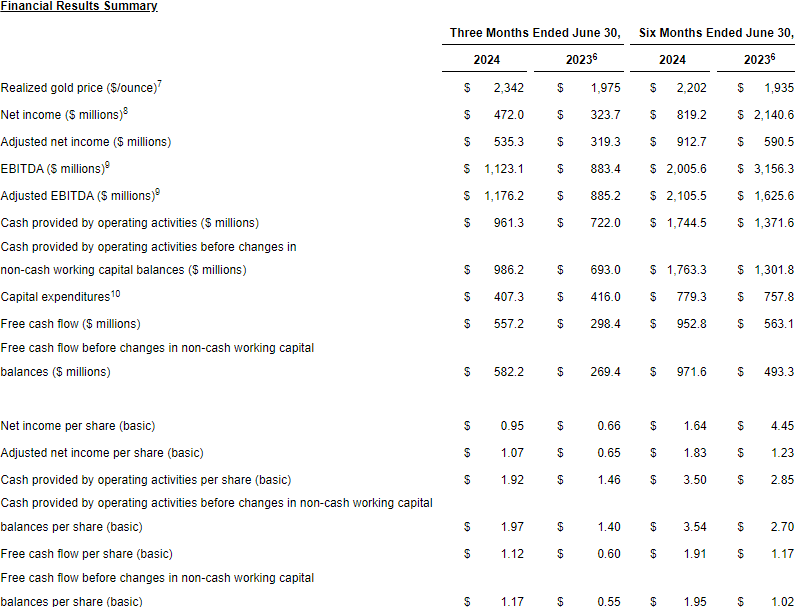

Net Income

- Second Quarter of 2024

- Net income was $472.0 million ($0.95 per share). This result includes the following items (net of tax): non-recurring tax adjustments and foreign currency translation losses on deferred tax liabilities of $25.7 million ($0.05 per share), derivative losses on financial instruments of $14.4 million ($0.03 per share), net asset disposals losses of $11.5 million ($0.02 per share) and foreign exchange and other losses of $11.7 million ($0.02 per share)

- Excluding the above items results in adjusted net income of $535.3 million or $1.07 per share

- Included in net income and not adjusted above, is a non-cash stock option expense of $2.1 million (less than $0.01 per share)

- et income of $472.0 million in the second quarter of 2024 increased compared to net income of $323.7 million in the prior-year period primarily due to stronger mine operating margins11 resulting from higher realized gold prices and higher sales volumes, partially offset by losses on derivative financial instruments in the current period, and higher income and mining tax expenses

- First Six Months of 2024 – Net income of $819.2 million decreased compared to the prior-year period primarily due to a remeasurement gain at Canadian Malartic in the prior period resulting from the application of purchase accounting relating to a business combination attained in stages, which requires the remeasurement of the Company’s previously held 50% interest in Canadian Malartic to fair value, partially offset by higher realized gold prices and higher sales volumes

6 Certain previously reported line items have been restated to reflect the final purchase price allocation related to the acquisition of the Canadian assets of Yamana Gold Inc. (the “Yamana Transaction”) including the 50% of Canadian Malartic that the Company did not own.

7 Realized gold price is calculated as gold revenues from mining operations divided by the number of ounces sold.

8 For the first quarter of 2023, includes a $1.5 billion revaluation gain on the 50% interest the Company owned in Canadian Malartic prior to the Yamana Transaction on March 31, 2023.

9 “EBITDA” means earnings before interest, taxes, depreciation, and amortization. EBITDA and adjusted EBITDA are non-GAAP measures or ratios that are not standardized financial measures under IFRS. For a description of the composition and usefulness of these non-GAAP measures and a reconciliation to net income see “Note Regarding Certain Measures of Performance” below.

10 Includes capitalized exploration.

11 Operating margin is a non-GAAP measure that is not a standardized measure under IFRS. For a description of the composition and usefulness of this non-GAAP measure and a reconciliation to net income see “Note Regarding Certain Measures of Performance” below.

Adjusted EBITDA

- Second Quarter of 2024 – Adjusted EBITDA increased when compared to the prior-year period primarily due to stronger mine operating margins from higher realized gold prices and higher sales volumes

- First Six Months of 2024 – Adjusted EBITDA increased when compared to the prior-year period primarily due to the reasons set out above for net income and as a result of the acquisition of the remaining 50% of Canadian Malartic

Cash Provided by Operating Activities

- Second Quarter and First Six Months of 2024 – Cash provided by operating activities and cash provided by operating activities before changes in non-cash working capital balances increased when compared to the prior-year periods primarily due to the reasons described above related to the increases in adjusted EBITDA

Free Cash Flow Before Changes in Non-cash Working Capital Balances

- Second Quarter and First Six Months of 2024 – Free cash flow before changes in non-cash working capital balances was a record for the third consecutive quarter and increased when compared to the prior-year periods due to the reasons described above related to cash provided by operating activities, as well as lower additions to property, plant and mine development

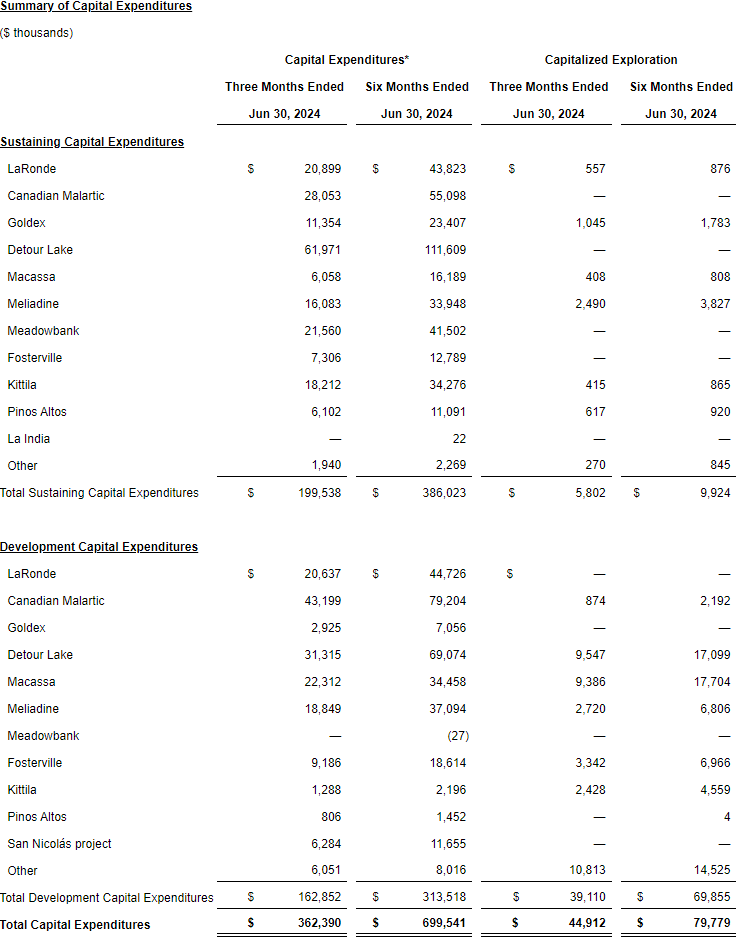

Capital Expenditures

In the second quarter of 2024, capital expenditures were $362.4 million and capitalized exploration expenditures were $44.9 million, for a total of $407.3 million. Expected capital expenditures (excluding capitalized exploration) remain in line with guidance for the full year 2024. As a result of the supplemental exploration budget approved of $50.0 million and the approval of the exploration ramp construction at Detour Lake and the exploration ramp and exploration shaft construction at Upper Beaver, capitalized exploration is expected to increase to approximately $186.8 million for the full year 2024. Further details are set out in the “2024 Guidance” section below.

The following table sets out a summary of capital expenditures (including sustaining capital expenditures12 and development capital expenditures12) and capitalized exploration in the second quarter of 2024 and the first six months of 2024.

12 Sustaining capital expenditures and development capital expenditures are non-GAAP measures that are not standardized financial measures under IFRS. For a discussion of the composition and usefulness of these non-GAAP measures and a reconciliation to additions to property, plant and mine development as set out in the consolidated statements of cash flows, see “Note Regarding Certain Measures of Performance” below.

* Excludes capitalized exploration

2024 Guidance

Production and Cost Guidance

Full year guidance remains unchanged at approximately 3.35 to 3.55 million ounces of gold, total cash costs per ounce of $875 to $925 and AISC per ounce of $1,200 to $1,250.

Capital Expenditure Guidance

Total expected capital expenditures (excluding capitalized exploration) for 2024 are still estimated to be between $1.6 billion to $1.7 billion.

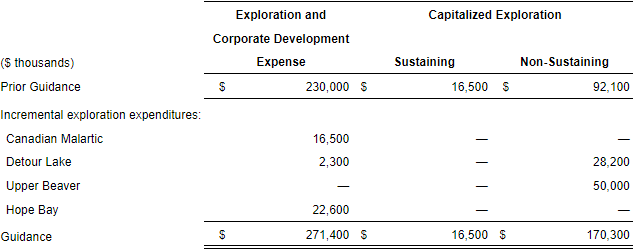

Exploration Guidance

The Company’s exploration and corporate development expense for 2024 is now expected to be approximately $271.4 million (compared to $230.0 million in the prior guidance). Based on positive exploration results in the first half of 2024 at Canadian Malartic, Detour Lake and Hope Bay, the Company has approved a supplemental budget of $50.0 million ($41.4 million expensed exploration and $8.6 million capitalized exploration). The supplemental exploration budget includes $16.5 million at Canadian Malartic for 84,500 metres of drilling, $10.9 million at Detour Lake for 55,000 metres of drilling (of which $8.6 million will be non-sustaining capitalized exploration expenditures) and $22.6 million at Hope Bay for 62,000 metres of drilling.

The Company’s capitalized exploration expenditures are now expected to be approximately $186.8 million (compared to $110.0 million in the prior guidance). To further study and de-risk the Detour Lake underground and Upper Beaver projects, the Company has approved $100.0 million and $200.0 million investments, respectively, over approximately three years. At Detour Lake, approximately $19.6 million is forecast to be spent in 2024 related to the construction of surface facilities and site preparation. At Upper Beaver, approximately $50.0 million is forecast to be spent in 2024 related to the construction of surface facilities, site preparation and the excavation of the shaft collar (of which $15.0 million was spent in the first half of 2024).

The breakdown of the incremental budget approved in exploration expense and capitalized exploration expenditures is set out in the table below.

Estimated 2024 Mid-Point Exploration and Corporate Development Expense and 2024 Capitalized Exploration Expenditures

Depreciation Guidance

Depreciation and amortization expense in 2024 is now expected to be at the lower end of the guidance range of $1.56 to $1.61 billion.

Record Cash Flow Generation Continues to Enhance Investment Grade Balance Sheet Alongside Continued Commitment to Shareholder Returns

Cash and cash equivalents increased by $397.4 million when compared to the prior quarter primarily due to higher cash provided by operating activities as a result of higher revenues from higher realized gold prices and higher sales volumes.

As at June 30, 2024, the Company’s long-term debt was $1,841.7 million, consistent with the prior quarter. No amounts were outstanding under the Company’s unsecured revolving bank credit facility as at June 30, 2024, and available liquidity remained at approximately $2.0 billion, not including the uncommitted $1.0 billion accordion feature.

The following table sets out the calculation of net debt13, which decreased by $396.7 million when compared to the prior quarter primarily as a result of higher cash and cash equivalents.

Subsequent to June 30, 2024, the Company completed two debt repayments. On July 24, 2024, $100.0 million was repaid with cash on hand on the 2012 Series B 5.02% Senior Notes on maturity and on July 31, 2024, $150.0 million was repaid with cash on hand of the $600.0 million outstanding on the term loan facility. The remaining $450.0 million of indebtedness under the term loan facility is due and payable by April 21, 2025.

In order to maintain financial flexibility, and consistent with past practice, the Company filed a new base shelf prospectus in the second quarter of 2024. The Company has no present intention to offer securities pursuant to the base shelf prospectus and the notice set out in this paragraph does not constitute an offer of any securities for sale or an offer to sell or the solicitation of an offer to buy any securities.

13 Net debt is a non-GAAP measure that is not a standardized financial measure under IFRS. For a description of the composition and usefulness of this non-GAAP measure and a reconciliation to long-term debt, see “Note Regarding Certain Measures of Performance” below.

Hedges

Approximately 73% of the Company’s remaining estimated Canadian dollar exposure for 2024 is hedged at an average floor price providing protection above 1.34 C$/US$. Approximately 27% of the Company’s remaining estimated Euro exposure for 2024 is hedged at an average floor price providing protection below 1.10 US$/EUR. Approximately 62% of the Company’s remaining Australian dollar exposure for 2024 is hedged at an average floor price providing protection above 1.46 A$/US$. Approximately 21% of the Company’s remaining estimated Mexican peso exposure for 2024 is hedged at an average floor price providing protection above 18.00 MXP/US$. The Company’s full year 2024 cost guidance is based on assumed exchange rates of 1.34 C$/US$, 1.10 US$/EUR, 1.45 A$/US$ and 16.50 MXP/US$.

With the 2024 sealift underway at the Company’s Nunavut operations, approximately 66% of the total diesel purchases have been completed, with initial deliveries in progress. Factoring in these purchases and anticipated deliveries, approximately 40% of the Company’s remaining estimated diesel exposure for 2024 is hedged at an average price of $0.76 per litre (excluding transportation and taxes), which is expected to reduce the Company’s exposure to diesel price volatility in 2024. The Company’s full year 2024 cost guidance is based on an assumed diesel price of $0.80 per litre (excluding transportation and taxes).

The Company will continue to monitor market conditions and anticipates continuing to opportunistically add to its operating currency and diesel hedges to strategically support its key input costs. Hedging positions are not factored into 2024 or future guidance.

Shareholder Returns

Dividend Record and Payment Dates for the Third Quarter of 2024

Agnico Eagle’s Board of Directors has declared a quarterly cash dividend of $0.40 per common share, payable on September 16, 2024 to shareholders of record as of August 30, 2024. Agnico Eagle has declared a cash dividend every year since 1983.

Expected Dividend Record and Payment Dates for the 2024 Fiscal Year

| Record Date | Payment Date |

| March 1, 2024* | March 15, 2024* |

| May 31, 2024* | June 14, 2024* |

| August 30, 2024** | September 16, 2024** |

| November 29, 2024 | December 16, 2024 |

*Paid

**Declared

Dividend Reinvestment Plan

Subsequent to the end of the second quarter of 2024, the Company’s board of directors approved an amendment to the terms of its dividend reinvestment plan (the “DRIP”) to provide the Company with the flexibility to adjust the discount provided under the DRIP to between no discount (0%) and 5%. The changes remain subject to pre-clearance by the Toronto Stock Exchange (the “TSX”). For the dividend payable on September 16, 2024 to shareholders of record as of August 30, 2024, provided the Company has received TSX pre-clearance for the amendment, the Company has determined that the discount provided for under the DRIP will be 1%. If the discount is altered or eliminated by the Company in the future, the Company will include information regarding the change in discount from such level in a news release prior to the effectiveness of the change.

For a copy of the amended and restated DRIP, which will be posted on receipt of TSX pre-clearance of the amendment, and for additional information on the Company’s DRIP see: Dividend Reinvestment Plan

International Dividend Currency Exchange

For information on the Company’s international dividend currency exchange program, please contact Computershare Trust Company of Canada by phone at 1.800.564.6253 or online at www.investorcentre.com or www.computershare.com/investor.

Normal Course Issuer Bid

In addition to the quarterly dividend, the Company believes that its NCIB is a flexible and complementary tool that is part of the Company’s overall capital allocation program and that generates value for shareholders. The Company received approval from the TSX to renew its NCIB in May 2024, allowing the Company to purchase up to $500.0 million of its common shares, subject to a maximum of 5% of its issued and outstanding common shares. Purchases under the NCIB may continue for up to one year from the commencement day on May 4, 2024. In the second quarter of 2024, the Company repurchased 763,043 common shares for an aggregate of $50.0 million through the NCIB, totalling 1,138,043 common shares repurchased for an aggregate of $69.9 million in the first six months of 2024.

Environment, Social and Governance Highlights

Reconciliation Action Plan

On July 10, 2024, the Company released its first Reconciliation Action Plan, reinforcing its commitment to reconciliation with Indigenous Peoples and communities. To the Company’s knowledge, it is the first mining company in Canada to publish a reconciliation action plan.

The Company’s reconciliation efforts, which began in Canada, have now expanded globally with many of its operations and offices situated on the traditional territories of different Indigenous Peoples. Agnico Eagleʹs commitment to reconciliation with Indigenous communities is built on three fundamental principles that have shaped the Company for over 65 years: (i) doing what’s right, (ii) respecting the rights of all individuals and groups, and (iii) creating value for stakeholders. These principles are reflected in the Reconciliation Action Plan, which was developed in collaboration with Indigenous communities and following consultations with over 250 employees, stakeholders and rights holders.

Organized into seven pillars that form the basis for the Company’s actions, the Reconciliation Action Plan aligns with the United Nations Declaration on the Rights of Indigenous People and integrates the Company’s existing Indigenous programs and initiatives into a central and comprehensive strategy aimed at delivering tangible benefits for Indigenous Peoples. It complements and strengthens the Company’s ongoing efforts aimed at contributing to the economic, social and emotional well-being of Indigenous Peoples and communities.

Agnico Eagle’s Reconciliation Action Plan with Indigenous Peoples is available on the Company’s website at www.agnicoeagle.com or can be downloaded directly by clicking here.

Dja Dja Wurrung Agreement Signed for Fosterville

On May 13, 2024, Agnico Eagle and leaders of the Dja Dja Wurrung People (“Djaara”) celebrated the signing of a historic agreement at Fosterville to develop and maintain a long-term relationship based on trust, mutual respect and collaboration. The agreement is called bakaru wayaparrangu, which means “in the middle, we all meet” in the Dja Dja Wurrung language. The agreement is the first to be established in the state of Victoria, Australia between traditional owners and a Company with an active mining operation. The agreement includes measures to increase the Djaara’s involvement in activities at Fosterville including training and employment opportunities, fostering business growth and safeguarding the environment, and is complemented by annual financial contributions.

2023 Climate Action Report

On July 31, 2024, the Company released its 2023 Climate Action Report, which provides an update regarding the Company’s 2023 greenhouse gas (“GHG”) emissions performance, climate strategy and progress achieved towards climate goals. The report is aligned with the recommendations of the Task Force on Climate-related Financial Disclosures and Towards Sustainable Mining Climate Change protocol, and supplements the Company’s 2023 Sustainability Report released in April 2024.

Highlights of the 2023 Climate Action Report include:

- GHG Emissions Targets – Agnico Eagle remains committed to achieving Net-Zero in absolute Scope 1 and Scope 2 carbon emissions by 2050 and maintains its interim carbon reduction target of 30% by 2030 (based on a 2021 baseline)

- Industry Leader for GHG Emissions Intensity (Scope 1 and 2) – The Company continues to be a gold industry leader with one of the lowest GHG emissions intensities amongst medium and large gold producers globally. In 2023, the Company’s global average GHG emissions intensity was 0.38 tonnes of CO2 equivalent per ounce of gold produced and all 11 active operations outperformed the 2022 industry average14. In 2023, GHG emissions decreased by 3% compared to 2022 and 5% compared to the Company’s 2021 baseline

- Supplier Engagement – Agnico Eagle has improved its Scope 3 methodology to incorporate updated and location-specific emission factors. The Company advanced its supplier engagement program to prioritize decarbonization partnership opportunities with its global supply chain, support improved understanding and increased data availability and to inform decision-making with a view to increasing the Company’s climate resilience and reducing Scope 3 emissions

- Decarbonization Strategy – Agnico Eagle prioritizes investments in technological innovation to support decarbonization focused on (i) energy efficiency, (ii) technology transition, which includes the increased use of battery electric vehicles across multiple operations, and (iii) renewable energy usage, which includes the deployment of cleaner power supplies at operations. Pinos Altos continues to maintain its power purchase agreement to obtain solar-generated electricity, and Kittila entered into a Certificate of Origin agreement to obtain 100% of its grid energy from zero-emission sources

- Climate Action Corporate Standard – The Company rolled out a Climate Action Corporate Standard establishing a comprehensive process to identify, assess and manage climate-related risks and opportunities across operations, provide guidance for the development of site Climate Action Plans and establish consistent GHG accounting practices for Scope 1, 2 and 3 emissions

- Climate Transition Assessments – Transition risk assessments have been completed for each operation with the support of subject matter experts. Learnings will be used in building site resilience and in engaging with employees and communities

Agnico Eagle’s 2023 Climate Action Report is available on the Company’s website at www.agnicoeagle.com or can be downloaded directly by clicking here.

14 Industry average of 0.83 tonnes of CO2 equivalent for Scope 1 and 2 emissions per ounce of gold produced, as per S&P Global Market Intelligence (2022)

Update on Key Value Drivers and Pipeline Projects

Highlights on key value drivers, including Upper Beaver, Odyssey, Detour Lake underground, Hope Bay and San Nicolás are set out below. Details on certain mine expansion projects (Detour Lake mill optimization, Meliadine Phase 2 expansion and Amaruq underground) are set out in the applicable operational sections of this news release.

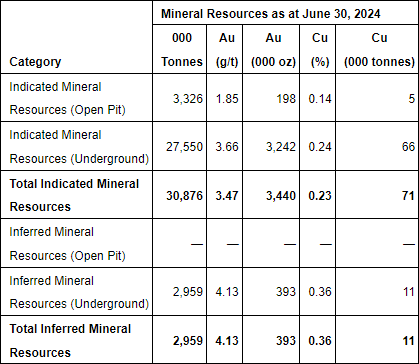

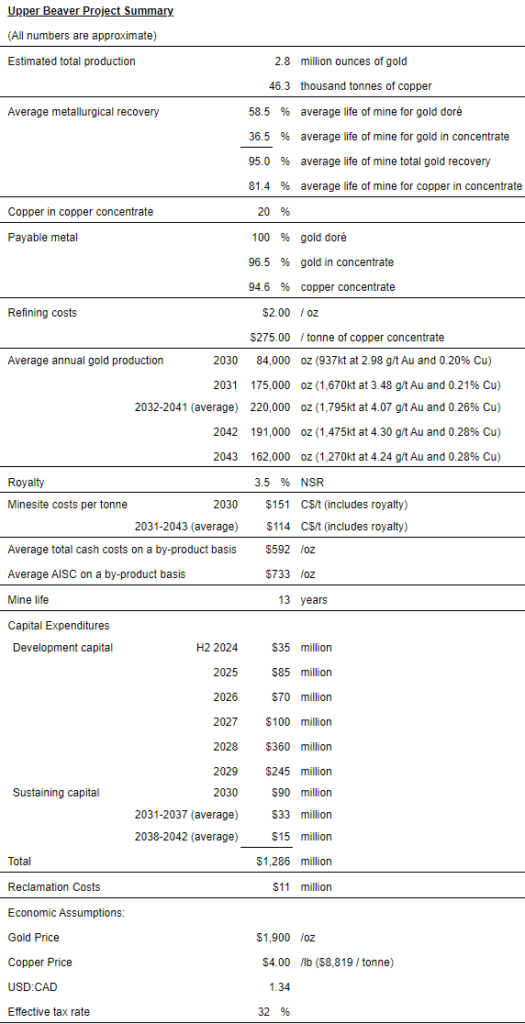

Upper Beaver Project

An internal evaluation of the Upper Beaver project was completed in June 2024. The study shows solid risk-adjusted economic returns for a standalone mine and mill scenario, based on a 5,000 tpd production rate. The main highlights of this study are set out below.

The forecast parameters surrounding the internal evaluation at the Upper Beaver project were based on a preliminary economic assessment, which is preliminary in nature and includes inferred mineral resources that are too speculative geologically to have economic considerations applied to them that would enable them to be categorized as mineral reserves and there is no certainty that the forecast production amounts or other outcomes will be realized. The basis for the preliminary economic assessment and the qualifications and assumptions made by the Qualified Persons who undertook the preliminary economic assessment are set out in this news release. The impact of the results of the preliminary economic assessment on the results of any pre-feasibility or feasibility study in respect of Upper Beaver are described in the Appendix under “MRMR update for Upper Beaver gold-copper project” and below.

Project Description

The Upper Beaver gold-copper project is located in the township of Gauthier, in northeastern Ontario, Canada, approximately 25 kilometres to the east of the town of Kirkland Lake. It is hosted in the Kirkland Lake-Larder Lake mining district, within the Company’s large Kirkland Lake camp. The district has a continuous history of mineral exploration and mining spanning more than 110 years and with an aggregate of over 42 million ounces of gold produced by various producers. The Company’s property portfolio in the Kirkland Lake camp is comprised of approximately 34,000 hectares, is approximately 35 kilometres long by 17 kilometres wide and includes Macassa, the satellite Near Surface and AK deposits, all of the past producing mines along the Main Break and several other past producing mines and several gold deposits, including Upper Beaver, Upper Canada and Anoki-McBean.

The Upper Beaver deposit’s gold-copper mineralization is mainly hosted in the Upper Beaver alkalic intrusive complex and the surrounding basalts it intruded, and is associated with disseminated pyrite and chalcopyrite, and magnetite-sulphide veining associated with strong magmatic-hydrothermal alteration. The mineralization occurs as elongated tabular bodies that strike northeast, dip steeply northwest and plunge 65 degrees to the northeast. The mineralization has been defined along a 400-metre strike length from surface to a depth of 2,000 metres and it remains open at depth.

The mineral reserve and mineral resource estimate at the Upper Beaver project has been updated to June 30, 2024 from the previous estimate at year-end 2023. The new estimate incorporates additional drill results, totalling 226,418 metres in 441 holes, and employs an improved mining concept with updated assumptions and drillhole database to reflect progress in the exploration program, project studies and optimization efforts. In the updated estimate, the mineral reserves have been reclassified as mineral resources that are supported by a positive internal preliminary economic assessment, which includes both indicated mineral resources and inferred mineral resources, that was completed in June 2024. As additional geotechnical fieldwork and metallurgical test work is completed through the remainder of the year, the Company anticipates that most indicated mineral resources will be converted into probable mineral reserves at year-end 2024.

A breakdown of the mineral resources used in the internal study is set out in the table below. Additional details on the Upper Beaver mineral resources at June 30, 2024 are set out in the Appendix of this news release. Additional details on the Upper Beaver mineral reserves and mineral resources at December 31, 2023, are set out in the Appendix and in the Company’s news release dated February 15, 2024.

The mining strategy developed for the Upper Beaver project is to mine the deposit mainly by conventional underground methods, although a small portion (approximately 10% of the mineral resource) will be mined via an open pit. The underground and open pit mines are expected to be developed within the same time frame.

Open pit operations will employ conventional methods of drilling, blasting and loading by excavator and wheel loader, with material haulage by truck to the various stockpiles, waste dump or directly to a crusher. Under current scenarios, production from the open pit is expected to occur from 2030 to 2034 at an average rate of approximately 2,000 tpd, of which 500 tpd will be stockpiled for later processing.

Current scenarios contemplate underground access through a main decline ramp as well as a shaft that is 1,220 metres deep and six metres in diameter. Four main stations are planned along the shaft, including a loading station at the bottom of the shaft. Ore and waste above 430 metres depth will be hauled to surface by trucks via the ramp. Ore and waste below 430 metres depth will be managed mainly through an ore and waste pass system and skipped to surface via the shaft. The underground mining concept is based on a long hole open stoping method, with sublevels every 30 metres and with stopes to be backfilled with paste and waste rock. The project is expected to use a combination of conventional and automated equipment, similar to what is currently used at the Company’s mines in the region. Production from underground, via ramp and shaft, could begin as early as 2030 and ramp-up to an average rate of approximately 4,500 tpd in 2035.

The plant is anticipated to use a conventional milling process, including a gravity circuit and a copper flotation circuit, with a design capacity of 5,000 tpd, an average total gold recovery of 95.0% and an average copper recovery of 81.0%. A copper concentrate will be produced with an expected copper content of approximately 20%. Approximately 36% of the gold is expected to report to the copper concentrate and approximately 59% of the gold is expected to be produced in the form of gold doré. Tailings will partly be returned underground as paste fill, with the remainder being disposed on a dry stack tailings storage facility.

Located in the Abitibi region, where the Company believes it has a demonstrated competitive advantage, the Company expects the project will benefit from internal technical expertise, local workforce and other regional support and synergies, including procurement and warehousing. The Company believes its strong presence in the region lowers the execution risk for the construction and operation of the project.

The Company believes Upper Beaver has the potential to produce an annual average of approximately 210,000 ounces of gold and 3,600 tonnes of copper, with initial production possible as early as 2030. Over an expected 13-year mine life, total payable gold and copper production are expected to be approximately 2.8 million ounces and 46,300 tonnes, respectively. The total cash costs per ounce on a by-product basis and AISC per ounce on a by-product basis are expected to be approximately $592 and $733, respectively. Initial capital costs are estimated at approximately $0.9 billion. Total sustaining capital expenditures are estimated at approximately $396 million.

Using a gold price of $1,900 per ounce, and a C$/US$ foreign exchange rate of 1.34, the Upper Beaver project has an after-tax internal rate of return (“IRR”) of 14% and an after-tax NPV (at a 5% discount rate) of approximately $625 million. Using a gold price of $2,300 per ounce, and a C$/US$ foreign exchange rate of 1.34, the Upper Beaver project has an after-tax IRR of 18% and an after-tax NPV (at a 5% discount rate) of approximately $1.01 billion. Additional details on the project are set out in the table below.

An agreement with local indigenous communities and environmental permits are in place for the advanced exploration phase of the project, including for the development of an exploration ramp and an exploration shaft and the collection of two bulk samples. Negotiations with indigenous communities are ongoing to establish an agreement for the production phase if a development decision is made. The Company is also advancing environmental impact assessments required for the Federal and Provincial approvals and permits that will be required for the construction and production phases following a development decision.

Based on the positive result of the internal evaluation and taking a measured approach, the Company has approved a $200.0 million investment over approximately three years to further de-risk the project. With this investment, the Company intends to develop an exploration ramp and an exploration shaft to depths of 160 metres and 760 metres, respectively, to establish underground drilling platforms and to collect bulk samples from the two most representative geological zones of the Upper Beaver deposit. The exploration ramp and exploration shaft will be sized to accommodate the potential production phase and are included in the initial capital expenditures estimate of approximately $0.9 billion.

Of the $200.0 million, approximately $35.0 million is forecast to be spent in the second half 2024, related primarily to the upgrade of the access road to the site, site surface preparation, construction of site facilities and excavation of the shaft collar. Preparatory site work commenced in early 2024 and approximately $15.0 million was spent in the first half of 2024. Excavation of the ramp and shaft sinking are expected to start in the second half of 2025.

Exploration Upside

Exploration results from recent years at Upper Beaver show the potential to increase the mineral resources and to convert inferred mineral resources at depth using underground access via the proposed exploration shaft and other underground infrastructure.

In the next stage of development, a bulk sampling program is planned in the two most representative geological zones of the Upper Beaver deposit. The first bulk sample will be taken from the upper level of the deposit, which is dominated by basaltic hosting lithologies, and will have the objective of testing selective mining assumptions in this area of the deposit. The second bulk sample will be taken from the lower level of the deposit, which is dominated by intrusion-suite hosting rocks, with the objective of validating mining parameters and grade variability at greater depth.

The Company believes the Upper Beaver project holds significant growth and synergy potential. The main deposit remains open at depth, as demonstrated by historical hole KLUB19-452W1 (presented in the Company’s news release dated April 25, 2019), which intersected 7.6 g/t gold and 0.36% copper over 3.4 metres at 1,983 metres depth and 1.2 g/t gold and 1.39% copper over 7.1 metres at 2,041 metres depth, approximately 300 metres down plunge from the nearest mineral resource block.

Additionally, multiple intrusions of similar nature to that associated with the emplacement of the Upper Beaver deposit have been identified in the immediate vicinity of the project. These intrusions are undergoing early-stage exploration efforts with the objective of developing targets for future regional diamond drilling programs.

[Upper Beaver –Composite Longitudinal Section]

Regional Potential

As a part of an Ontario regional exploration budget for 2024 totalling $13.5 million for 19,400 metres of drilling, a planned surface exploration campaign has included drill holes to test the deep extensions of the Main Break east of the underground infrastructure of the SMC at Macassa and below historical mining levels of the Kirkland Lake camp to provide support for future underground exploration drifts.

Opportunities for future synergies in the Kirkland Lake camp include multiple known deposits owned by the Company. The nearest deposit to Upper Beaver is the Upper Canada past-producing gold mine, which lies 6 kilometres west-southwest. As at December 31, 2023, Upper Canada was estimated to contain 10.4 million tonnes of indicated mineral resources grading 2.15 g/t gold for 722,000 ounces of gold and 18.6 million tonnes of inferred mineral resources grading 3.11 g/t gold for 1.9 million ounces of gold, in open pit and underground mineral resources.

The Anoki-McBean deposits lie 6.5 kilometres southwest of Upper Beaver and host indicated mineral resources of 3.9 million tonnes grading 2.77 g/t gold for 349,000 ounces of gold and inferred mineral resources of 867,000 tonnes grading 3.84 g/t gold for 107,000 ounces of gold as at December 31, 2023.

Several other historical mineralized occurrences in the Kirkland Lake camp warrant additional exploration with the objective of potentially providing future mill feed at either Macassa and/or the Upper Beaver project, while benefiting from synergies with existing or future mining operations.

[Kirkland Lake Regional – Property and Geology Map]

Odyssey Project

In the second quarter of 2024, ramp development continued to exceed targets, reaching the third production level of East Gouldie (a depth of 832 metres) as at June 30, 2024. Equipment remotely tele-operated from surface (scoops, trucks, jumbos and cable bolters) has helped maintain the development performance, offsetting the increase in depth. The Company continued to develop the main ventilation system, with the completion of the future exhaust raise between levels 26 and 36 and the development of the fresh air ramp between Odyssey South and East Gouldie.

In the second quarter of 2024, shaft sinking activities advanced at an average rate of 2.5 metres per day, slightly ahead of target, and as at June 30, 2024, the shaft reached a depth of 680 metres. The pre-sinking of the shaft between levels 54 and 66 was completed in the second quarter and the remainder of the shaft will be excavated by conventional sinking methods. The excavation of station 54 was completed in the quarter and the excavation of the temporary loading pocket between levels 60 and 64 is ongoing, with construction expected to be initiated in September 2024 and commissioning expected in mid-2025.

Surface construction progressed as planned and on budget in the second quarter of 2024. Areas of focus included the main hoist building, phase 2 of the paste plant (to expand capacity to 20,000 tpd) and the operational complex. At the main hoist building, installation of the mechanical components of the service hoist was completed in the second quarter of 2024 and the installation of the electrical components and controls is ongoing. The conceptual engineering for the paste plant expansion was completed in the second quarter of 2024 and detailed engineering has started. The contractor for the construction of the main office and service building was selected and is expected to be on site in the third quarter of 2024 with construction expected to be completed by the end of 2025.

Exploration drilling at Odyssey totalled 24,182 metres during the second quarter (50,442 metres during the first half of 2024) with seven underground drill rigs and six surface drill rigs in operation, primarily targeting the East Gouldie and Odyssey deposits.

Drilling into the lower eastern extension of the East Gouldie mineralized envelope produced highlights that included: hole MEX24-311 returning 4.5 g/t gold over 6.5 metres at 1,571 metres depth, 770 metres east of the East Gouldie mineral reserves; hole MEX24-311Z returning 8.7 g/t gold over 3.8 metres at 1,687 metres depth, approximately 110 metres below hole MEX24-311; and hole MEX23-310ZA returning 2.3 g/t gold over 15.3 metres at 1,694 metres depth, 410 metres east of the mineral reserves.

The drilling remains on track to achieve a 150-metre drill spacing in an area that spans over 900 metres in strike length and 700 metres in elevation in the eastern extension of East Gouldie, with the objective of adding new inferred mineral resources for year-end 2024.

Drilling into a previously untested gap in the western extension of the East Gouldie deposit also intersected significant results, with hole MEX24-312 returning 2.5 g/t gold over 30.0 metres at 1,473 metres depth, 85 metres west of the East Gouldie mineral reserves; and hole MEX24-312Z returning 2.2 g/t gold over 10.5 metres at 1,414 metres depth, 260 metres west of the mineral reserves. These results are anticipated to have a positive impact on the mineral resource estimate at year-end 2024.

At a shallower depth, hole MEX24-314 intersected 2.8 g/t gold over 11.4 metres at 335 metres depth, including 9.8 g/t gold over 2.0 metres at 329 metres depth, in a potential extension of the East Malartic deposit. Follow-up drilling is planned in this new area of interest before the end of the year.

Selected recent drill intercepts from the East Gouldie and East Malartic deposits at the Odyssey mine are set out in the table and composite longitudinal section below.

| Drill hole | Deposit | From(metres) | To(metres) | Depth of midpoint below surface (metres) | Estimatedtrue width(metres) | Gold grade(g/t) (uncapped) | Gold grade(g/t)(capped)* |

| MEX23-310ZA | East Gouldie | 1,928.1 | 1,945.4 | 1,694 | 15.3 | 2.3 | 2.3 |

| MEX24-311 | East Gouldie | 1,890.5 | 1,897.5 | 1,571 | 6.5 | 4.5 | 4.5 |

| MEX24-311Z | East Gouldie | 1,971.3 | 1,975.7 | 1,687 | 3.8 | 8.7 | 8.7 |

| MEX24-312 | East Gouldie | 1,634.0 | 1,666.4 | 1,473 | 30.0 | 2.5 | 2.5 |

| MEX24-312Z | East Gouldie | 1,626.8 | 1,638.0 | 1,414 | 10.5 | 2.2 | 2.2 |

| MEX24-314 | East Malartic | 421.0 | 441.0 | 335 | 11.4 | 2.8 | 2.8 |

| including | 421.0 | 424.5 | 329 | 2.0 | 9.8 | 9.8 |

*Results from East Gouldie and East Malartic use capping factors of 20 g/t gold and 40 g/t gold, respectively.

[Odyssey mine – Composite Longitudinal Section]

Based on the positive results from the exploration program near the Odyssey mine during the first half of 2024, the Company has approved a supplemental exploration budget of $12.0 million for 68,000 metres of near-mine drilling during the second half of the year. The objective is to further expand the East Gouldie deposit footprint laterally and add inferred mineral resources in support of a potential future Shaft #2 and the broader “Fill the Mill” strategy at the Canadian Malartic complex.

In addition, the regional exploration program at Canadian Malartic is receiving a supplemental exploration budget of $4.5 million for 16,500 metres of additional drilling during the second half of 2024, to further investigate the eastern portion of the Canadian Malartic property package in support of the Fill the Mill strategy.

These supplemental budgets are in addition to the Company’s previously disclosed exploration budget for 2024 at Canadian Malartic of approximately $20.4 million for 137,000 metres of drilling at Odyssey and at regional targets.

Detour Lake

On June 19, 2024, the Company released the results of a technical study reflecting the potential for a concurrent underground operation to accelerate access to higher grade ore and to increase annual production to approximately one million ounces for 14 years starting in 2030 (see the Company’s news release dated June 19, 2024).

The technical study assumed an underground mining rate of approximately 11,200 tpd (equivalent to 4.0 million tonnes per annum (“Mtpa”)) starting in 2030, combined with a mill expansion to 79,450 tpd (equivalent to 29 Mtpa) starting in 2028. Annual production is expected to increase by approximately 43% or 300,000 ounces of gold per year, from 2030 to 2043 to approximately one million ounces per year when compared to average annual production in years 2024 to 2029. The underground project and mill throughput optimization to 29 Mtpa are expected to generate an after-tax IRR of approximately 18% using a gold price assumption of $1,900 per ounce and a C$/US$ foreign exchange rate of 1.34. At a gold price assumption of $2,300 per ounce and a C$/US$ foreign exchange rate of 1.34, the underground project and mill throughput optimization to 29 Mtpa are expected to generate an after-tax IRR of approximately 25%.

Based on strong risk-adjusted returns for the Detour Lake underground project, the Company has approved a $100.0 million investment over approximately three years to develop a 2.0-kilometre exploration ramp to a depth of 270 metres in order to collect a bulk sample and to facilitate infill and expansion drilling of the current underground mineral resource. Approximately $19.6 million is forecast to be spent in the second half of 2024 related to the construction of surface facilities and site preparation.

Exploration drilling at Detour Lake during the second quarter of 2024 totalled 72,000 metres (130,000 metres during the first half of 2024), including infill drilling into the newly defined high-grade corridor at underground depths in the West Pit zone and infill drilling into the West Pit Extension zone at underground depths immediately west of the West Pit mineral resources and next to the proposed exploration ramp for the underground project.

In the high-grade corridor in the West Pit zone, highlights included: hole DLM24-843 returning 4.0 g/t gold over 22.3 metres at 413 metres depth, including 18.7 g/t gold over 2.1 metres at 414 metres depth; hole DLM24-874 returning 2.5 g/t gold over 10.3 metres at 291 metres depth and 4.4 g/t gold over 30.1 metres at 550 metres depth, including 17.6 g/t gold over 3.9 metres at 557 metres depth; and hole DLM24-897E returning 26.9 g/t gold over 2.8 metres at 235 metres depth and 3.3 g/t gold over 11.1 metres at 261 metres depth.

To the west in the West Pit zone near the proposed exploration ramp, highlights included: hole DLM24-873 returning 37.3 g/t gold over 3.5 metres at 282 metres depth; and hole DLM24-930A returning 20.6 g/t gold over 5.5 metres at 280 metres depth and 1.8 g/t gold over 60.5 metres at 348 metres depth.

From infill drilling into the West Pit Extension zone, highlights included: hole DLM24-884 returning 4.3 g/t gold over 22.5 metres at 429 metres depth, including 24.5 g/t gold over 3.5 metres at 432 metres depth, and 3.7 g/t gold over 13.4 metres at 551 metres depth; hole DLM24-895AW returning 28.8 g/t gold over 3.6 metres at 570 metres depth; and hole DLM24-873 returning 37.3 g/t gold over 3.5 metres at 282 metres depth.

Selected recent drill intercepts from the West Pit Underground and West Pit Extension zones at Detour Lake are set out in the table and composite longitudinal section below.

| Drill hole | Zone | From(metres) | To(metres) | Depth of midpoint below surface (metres) | Estimatedtrue width(metres) | Gold grade(g/t) (uncapped)* |

| DLM24-839 | West Pit Extension | 353.0 | 362.0 | 321 | 7.2 | 5.2 |

| and | West Pit Extension | 395.0 | 419.4 | 365 | 19.6 | 3.9 |

| including | 398.0 | 402.0 | 358 | 3.2 | 12.6 | |

| DLM24-843 | West Pit Underground | 505.8 | 530.3 | 413 | 22.3 | 4.0 |

| including | 519.2 | 521.5 | 414 | 2.1 | 18.7 | |

| DLM24-851 | West Pit Extension | 350.0 | 392.3 | 318 | 36.1 | 2.6 |

| including | 375.3 | 378.7 | 323 | 2.9 | 23.5 | |

| DLM24-855 | West Pit Extension | 481.9 | 509.0 | 433 | 22.8 | 2.4 |

| including | 486.0 | 495.0 | 429 | 7.6 | 5.1 | |

| DLM24-860 | West Pit Extension | 583.9 | 619.0 | 524 | 30.2 | 2.2 |

| including | 583.9 | 598.0 | 515 | 12.1 | 4.4 | |

| DLM24-870 | West Pit Underground | 207.6 | 228.0 | 182 | 17.7 | 3.3 |

| including | 221.1 | 225.0 | 186 | 3.4 | 11.0 | |

| DLM24-871 | West Pit Underground | 378.5 | 396.0 | 313 | 15.6 | 4.7 |

| including | 378.5 | 383.6 | 309 | 4.5 | 13.6 | |

| DLM24-873 | West Pit Underground | 346.1 | 350.0 | 282 | 3.5 | 37.3 |

| DLM24-874 | West Pit Underground | 385.0 | 396.0 | 291 | 10.3 | 2.5 |

| and | 764.0 | 795.0 | 550 | 30.1 | 4.4 | |

| including | 789.0 | 793.0 | 557 | 3.9 | 17.6 | |

| DLM24-884 | West Pit Underground | 526.3 | 551.0 | 429 | 22.5 | 4.3 |

| including | 540.6 | 544.4 | 432 | 3.5 | 24.5 | |

| and | West Pit Underground | 696.0 | 710.5 | 551 | 13.4 | 3.7 |

| DLM24-891C | West Pit Underground | 635.0 | 662.0 | 562 | 23.4 | 1.7 |

| including | 650.8 | 662.0 | 569 | 9.7 | 3.4 | |

| DLM24-895AW | West Pit Extension | 676.0 | 680.0 | 570 | 3.6 | 28.8 |

| DLM24-897E | West Pit Underground | 305.0 | 308.0 | 235 | 2.8 | 26.9 |

| and | West Pit Underground | 336.0 | 348.0 | 261 | 11.1 | 3.3 |

| DLM24-899A | West Pit Extension | 578.0 | 595.9 | 495 | 15.8 | 4.4 |

| DLM24-903 | West Pit Extension | 403.0 | 418.0 | 344 | 13.2 | 3.6 |

| and | 438.0 | 446.8 | 369 | 7.8 | 12.8 | |

| DLM24-908E | West Pit Underground | 727.0 | 775.0 | 576 | 45.6 | 2.1 |

| including | 764.0 | 774.0 | 589 | 9.5 | 6.5 | |

| and | West Pit Underground | 791.0 | 819.0 | 613 | 26.7 | 2.1 |

| including | 800.0 | 808.0 | 612 | 7.6 | 5.5 | |

| DLM24-911A | West Pit Extension | 722.3 | 750.2 | 636 | 24.6 | 2.4 |

| including | 730.9 | 734.0 | 633 | 2.7 | 13.9 | |

| and | West Pit Extension | 761.0 | 792.0 | 668 | 27.4 | 2.4 |

| including | 779.8 | 782.9 | 672 | 2.7 | 16.8 | |

| and | West Pit Extension | 827.6 | 835.0 | 711 | 6.6 | 9.5 |

| DLM24-916W | West Pit Extension | 460.7 | 498.1 | 408 | 32.2 | 3.2 |

| including | 486.8 | 491.7 | 416 | 4.2 | 12.8 | |

| DLM24-923 | West Pit Extension | 603.4 | 630.0 | 520 | 23.2 | 3.3 |

| including | 603.4 | 606.5 | 520 | 2.7 | 17.4 | |

| DLM24-927 | West Pit Extension | 445.8 | 450.7 | 375 | 4.3 | 15.7 |

| DLM24-930A | West Pit Underground | 349.0 | 355.0 | 280 | 5.5 | 20.6 |

| and | West Pit Underground | 411.0 | 476.4 | 348 | 60.5 | 1.8 |

*Results from Detour Lake are uncapped.

[Detour Lake – Composite Longitudinal Section]

Further details on the mine-site and regional exploration programs at Detour Lake in 2024 are set out in the Detour Lake-focused news release dated June 19, 2024.

With the success of the exploration program at Detour Lake during the first half of the year, the Company has approved a supplemental exploration budget of $10.9 million for 55,000 metres of drilling during the second half of 2024 to infill and expand the underground high-grade corridor to accelerate the de-risking of the underground project. This is in addition to the previously disclosed exploration budget for 2024 at Detour Lake of $27.7 million for 160,000 metres of drilling.

Hope Bay – Step-Out Drilling Continues to Extend Madrid’s High-Grade Patch 7 Zone at Depth and Laterally

Exploration drilling at Hope Bay during the second quarter of 2024 totalled 35,400 metres (66,100 metres during the first half of 2024) and continued to return strong results at the Madrid deposit within the Patch 7 zone and in the gap area between the Patch 7 and Suluk zones.

Infill drilling into the high-grade shoot immediately north of the Patch 7 mineral resource was highlighted by hole HBM24-206A returning 26.7 g/t gold over 2.8 metres at 405 metres depth, including 75.0 g/t gold over 0.9 metres at 404 metres depth, and 17.0 g/t gold over 25.8 metres at 419 metres depth, including 35.6 g/t gold over 6.5 metres at 412 metres depth; hole HBM24-207 returning 7.2 g/t gold over 8.1 metres at 559 metres depth, including 8.7 g/t gold over 4.5 metres at 558 metres depth; and hole HBM24-209 returning 30.8 g/t gold over 2.4 metres at 559 metres depth.

The high-grade shoot remains open both up-plunge and down-plunge with significant potential for mineral resource expansion.

This emerging new mineralized area continues to show excellent continuity as well as grades and thicknesses greater than average for the Madrid deposit. It is anticipated that the drilling program in this area in 2024 will have positive impacts on the mineral resource estimate at year-end 2024 and on mining scenarios for potential project redevelopment.

At shallower depths in the same area of Patch 7, hole HBM24-191 returned 9.7 g/t gold over 6.3 metres at 242 metres depth and hole HBM24-201 returned 5.3 g/t gold over 18.0 metres at 278 metres depth. Drilling in this shallower area is confirming the presence of the same structures and favourable host rocks encountered in the main Patch 7 mineral resources located several hundred metres to the south.

Exploration during the second quarter also included widely spaced, expansion drilling at greater depth approximately 600 metres to the north in the largely untested gap area between the Patch 7 and Suluk zones, highlighted by hole HBM24-177B returning 9.5 g/t gold over 8.6 metres at 750 metres depth, including 15.5 g/t gold over 3.7 metres at 753 metres depth; and hole HBM24-183 returning 14.1 g/t gold over 5.0 metres at 577 metres depth, including 25.1 g/t gold over 2.3 metres at 575 metres depth.

Selected recent drill intercepts from the Patch 7 zone at the Madrid deposit are set out in the table and composite longitudinal section below.

| Drill hole | From(metres) | To(metres) | Depth of midpoint below surface (metres) | Estimatedtrue width(metres) | Gold grade(g/t)(uncapped) | Gold grade(g/t)(capped)* |

| HBM24-177B | 864.5 | 883.8 | 750 | 8.6 | 9.5 | 9.5 |

| including | 873.9 | 882.0 | 753 | 3.7 | 15.5 | 15.5 |

| HBM24-183 | 684.4 | 693.5 | 577 | 5.0 | 19.0 | 14.1 |

| including | 684.4 | 688.6 | 575 | 2.3 | 35.8 | 25.1 |

| HBM24-188 | 609.4 | 633.6 | 475 | 15.2 | 5.6 | 5.6 |

| including | 611.0 | 620.0 | 471 | 5.7 | 4.6 | 4.6 |

| including | 626.0 | 633.6 | 481 | 4.8 | 10.9 | 10.9 |

| HBM24-189 | 552.3 | 581.8 | 443 | 12.7 | 6.0 | 6.0 |

| including | 552.3 | 575.2 | 441 | 9.9 | 6.9 | 6.9 |

| HBM24-191 | 289.1 | 297.0 | 242 | 6.3 | 9.7 | 9.7 |

| HBM24-201 | 357.0 | 375.0 | 278 | 18.0 | 10.8 | 5.3 |

| HBM24-206A | 529.0 | 532.0 | 405 | 2.8 | 28.0 | 26.7 |

| including | 529.0 | 530.0 | 404 | 0.9 | 79.0 | 75.0 |

| and | 539.1 | 566.0 | 419 | 25.8 | 20.8 | 17.0 |

| including | 539.1 | 546.0 | 412 | 6.5 | 50.7 | 35.6 |

| HBM24-207 | 634.8 | 651.0 | 559 | 8.1 | 7.2 | 7.2 |

| including | 637.1 | 646.1 | 558 | 4.5 | 8.7 | 8.7 |

| HBM24-209 | 643.0 | 646.0 | 559 | 2.4 | 53.7 | 30.8 |

*Results from the Madrid deposit at Hope Bay use a capping factor ranging from 50 g/t to 75 g/t gold depending on the mineralized domain.

[Madrid Deposit at Hope Bay – Composite Longitudinal Section]

Given the positive drill results at Madrid during the first half of 2024, the Company has approved a supplemental exploration budget at Hope Bay for the second half of 2024 of $22.6 million for an additional 62,000 metres of drilling to infill and expand Patch 7 to accelerate mineral reserve addition in advance of a potential project decision in 2025-26. This is in addition to the previously disclosed budget for 2024 at the Hope Bay project of $22.0 million for 50,000 metres of drilling.

In early July, the Company finalized an asset purchase agreement with North Arrow Minerals Inc. to acquire a 100% interest in the Oro gold property in the northeastern extension of the Hope Bay gold belt for a cash consideration of C$1.75 million. The Oro property comprises 4,103 hectares consisting of five leases with multiple, historical near-surface gold mineralization occurrences.

San Nicolás Copper Project

In the second quarter of 2024, Minas de San Nicolás continued engagement with government and stakeholders in support of the permit review and continued to advance feasibility study work, with plans to initiate detailed engineering in the first half of 2025. The Minas de San Nicolás team submitted the change of land use permit application (“ETJ”) on June 14, 2024 and a Supplementary Information Package in response to the regulator’s enquiries on their MIA-R permit application (“EIA”) on July 5, 2024. Project approval is expected to follow, subject to receipt of permits and the results of the feasibility study.

ABITIBI REGION, QUEBEC

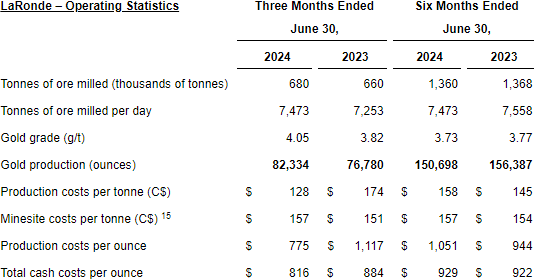

LaRonde – Strong Operational Performance Driven by Higher Grades; Automation Initiatives at LaRonde Zone 5 Continue to Exceed Targets

Gold Production

- Second Quarter of 2024 – Gold production increased when compared to the prior-year period primarily due to a higher volume of ore mined and milled driven by strong operational performance and higher gold grades as expected under the mining sequence, partially offset by lower recovery

- First Six Months of 2024 – Gold production decreased when compared to the prior-year period due to lower gold grades and a lower volume of ore milled

Production Costs

- Second Quarter of 2024 – Production costs per tonne decreased when compared to the prior-year period primarily due to the higher volume of ore milled in the current period, partially offset by the timing of inventory sales and higher milling and royalty costs at the LaRonde mine. Production costs per ounce decreased when compared to the prior-year period primarily due to higher gold grades and lower production costs per tonne

- First Six Months of 2024 – Production costs per tonne increased when compared to the prior-year period primarily due to stockpile consumption, the timing of inventory sales, higher milling and royalty costs at the LaRonde mine and lower volumes of ore milled. Production costs per ounce increased when compared to the prior-year period primarily due to higher production costs per tonne and lower gold grades

Minesite and Total Cash Costs

- Second Quarter of 2024 – Minesite costs per tonne increased when compared to the prior-year period primarily due to higher milling and royalty costs at the LaRonde mine, partially offset by higher volume of ore milled. Total cash costs per ounce decreased when compared to the prior-year period primarily due to higher gold grades, partially offset by higher minesite costs per tonne

- First Six Months of 2024 – Minesite costs per tonne increased when compared to the prior-year period primarily due to stockpile consumption and higher milling and royalty costs and lower volume of ore milled. Total cash costs per ounce increased when compared to the prior-year period primarily due to lower gold grades and higher minesite costs per tonne

15 Minesite costs per tonne is a non-GAAP measure that is not standardized under IFRS and is reported on a per tonne of ore milled basis. For a description of the composition and usefulness of this non-GAAP measure and a reconciliation to production costs see “Note Regarding Certain Measures of Performance” below.

Highlights

- Gold production in the quarter was higher than forecast as a result of higher grades and higher volume milled

- The Company continued its automation initiatives at the LaRonde zone 5 mine (“LZ5”) and exceeded its automation target by 22%. Approximately 1,800 tpd were moved during the quarter through automated scoops and trucks, which contributed to the strong overall performance of the site at an average 3,450 tpd

- The LZ5 processing facility was placed on care and maintenance during the third quarter of 2023 and is on track to restart in the third quarter of 2024. During the downtime, the Company continues to overhaul the facility’s leach tanks and is refurbishing the ore silo. Ore from LZ5 will continue to be processed at the LaRonde mill until the restart of the LZ5 processing facility

- A shutdown was scheduled for the third quarter of 2024 for 14 days at the LaRonde mine and 11 days at the LaRonde mill and was completed in July

- On June 24, 2024, a seismic event of magnitude 4.1 on the Richter scale, occurred at the LaRonde mine. Safety protocols were followed, the mine was evacuated and no workers were injured. The dynamic ground support performed as designed. While the mine was shutdown for approximately two days, the mill continued to operate at normal levels using surface stockpiles. Site-specific expertise in mitigating seismic risk has been developed by the Company over many years of operations at LaRonde. The Company’s objective remains to address the seismic risk by continuously improving mitigation measures to keep a safe work environment while maintaining reasonable production rates. These mitigation measures include non-entry protocols, dynamic ground support and, increasingly, remote operation from surface

- At the LaRonde mill, the focus remained on improving mill recoveries by optimizing the blending of ore from the LaRonde mine, 11-3 zone, LZ5, Goldex and Akasaba West

- During the quarter, LaRonde was recognized for environmental and social performance, receiving the following awards:

- TSM Excellence Award from the Mining Association of Canada for the transition to filtered tailings management – this award acknowledges innovative projects and initiatives that support sustainable development

- Community relations award from the Quebec Mining Association (“QMA”) – recognition of the collaboration agreement with the Abitibiwinni First Nations and the Nikan Project, which facilitates integration and retention of Indigenous workers

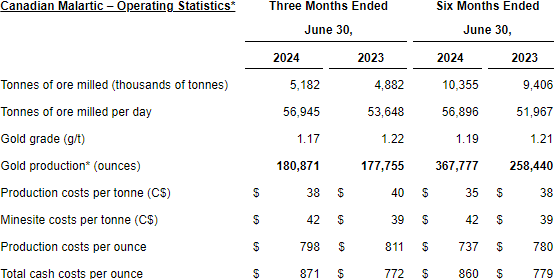

Canadian Malartic – Higher Tonnes Milled Drive Strong Production; Record Development Metres and Production from Odyssey South

* Gold production reflects Agnico Eagle’s 50% interest in Canadian Malartic up to and including March 30, 2023 and 100% interest thereafter. Tonnage of ore milled is reported on a 100% basis for both periods.

Gold Production

- Second Quarter of 2024 – Gold production increased when compared to the prior-year period primarily due to higher throughput resulting from strong operational performance at the Barnat pit and Odyssey mine, partially offset by lower gold grades from increased ore sourced from the low-grade stockpile

- First Six Months of 2024 – Gold production increased when compared to the prior-year period due to the increase in the Company’s ownership percentage between periods from 50% to 100% as a result of the closing of the acquisition of the Yamana Transaction and higher throughput, partially offset by lower gold grades resulting from increased ore sourced from the low-grade stockpile

Production Costs

- Second Quarter of 2024 – Production costs per tonne decreased when compared to the prior-year period primarily due to a higher volume of ore milled and the timing of inventory adjustments during the comparative period. Production costs per ounce decreased when compared to the prior-year period due to more ounces of gold produced in the current period

- First Six Months of 2024 – Production costs per tonne decreased when compared to the prior-year period primarily due to a higher volume of ore milled and the timing of inventory adjustments during the comparative period. Production costs per ounce decreased when compared to the prior-year period due to lower production costs per tonne, partially offset by lower gold grades in the current period

Minesite and Total Cash Costs

- Second Quarter of 2024 – Minesite costs per tonne increased when compared to the prior-year period due to the milling of low-grade stockpiles and higher royalty costs during the quarter, partially offset by higher volume of ore milled. Total cash costs per ounce increased when compared to the prior-year period primarily due to the same factors that resulted in higher minesite costs per tonne and lower gold grades in the current period

- First Six Months of 2024 – Minesite costs per tonne increased when compared to the prior-year period due to the consumption of low-grade stockpiles and higher royalty costs, partially offset by higher volume of ore milled. Total cash costs per ounce increased when compared to the prior-year period primarily due to the same factors that resulted in higher minesite costs per tonne and lower gold grades in the current period

Highlights

- Higher mill throughput, higher gold grades from the Barnat pit due to mine sequencing and higher mill recoveries than planned, along with the record production from Odyssey, resulted in better than planned quarterly gold production at Canadian Malartic

- At Odyssey South, total metres developed during the quarter were a record at 3,870 metres. Gold production and mining rate were above plan at approximately 22,300 ounces of gold and 3,750 tpd, respectively. The strong operational performance was supported by higher than planned equipment availability and the addition of 65 tonne haulage trucks

- Stope reconciliation at Odyssey South remains positive, primarily from the contribution of the internal zones, which resulted in approximately 13% more ounces of gold produced than anticipated during the second quarter

- At the Canadian Malartic pit, the Company continued the construction of the central berm (approximately 95% complete at June 30, 2024) in preparation for in-pit tailings disposal, which began in July 2024

- An extended shutdown at the Canadian Malartic mill is planned for the third quarter of 2024 totalling 10 days (approximately an additional 5 days from the original plan) due to the acceleration of maintenance work on the tailings thickener drive assembly

- An update on the Odyssey mine development, construction and exploration highlights is set out in the Update on Key Value Drivers and Pipeline Projects section above

- During the quarter, Canadian Malartic was recognized for its health and safety performance and received the following awards:

- John T. Ryan Eastern Canada Regional Safety award from the Canadian Institute of Mining, Metallurgy and Petroleum – awarded to an open pit mine which experienced the lowest reportable injury frequency in the previous year

- F.J. O’Connell surface operations award from the QMA – recognizing workplace health and safety performance of QMA members

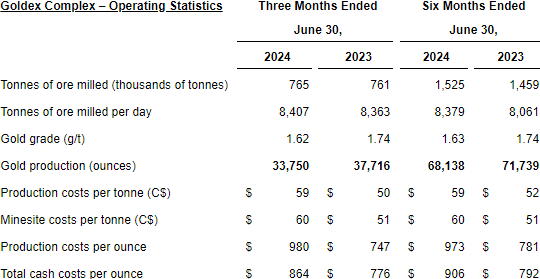

Goldex – Record Tonnage Milled Since Re-Start in 2013; Production from Deep 2 Zone Commenced

Gold Production

- Second Quarter of 2024 – Gold production decreased when compared to the prior-year period primarily due to lower average gold grades resulting from increased ore sourced from Akasaba West

- First Six Months of 2024 – Gold production decreased when compared to the prior-year period primarily due to lower average gold grades resulting from increased ore sourced from Akasaba West, partially offset by a higher volume of ore processed

Production Costs